Institute of Physics of Materials AS CR, v. v. i. > Groups > Advanced High-temperature Materials Group

Following topics have been studied in last five years:

Creep test machines of our own design with direct load

Creep test machines of our own design with direct load

Contact person: Ing. Petr Dymáček, Ph.D.

6 creep test machines of own design with direct load for performing of tensile creep tests in constant load mode

Creep test system Zwick/Roell KAPPA DS 50 kN, with furnace up to 1200 °C

Creep test system Zwick/Roell KAPPA DS 50 kN, with furnace up to 1200 °C

Contact person: Ing. Petr Dymáček, Ph.D.

Creep test system Zwick/Roell KAPPA DS 50 kN, with furnace up to 1200 °C, testing in air

Thermal Desorption Spectroscopy Instrument

Thermal Desorption Spectroscopy Instrument

Contact person:

The instrument is consists of a horizontal furnace CLASSIC 4011T, a quadrupole mass spectrometer PFEIFFER PrismaPro QM 250 M1 and a vakuum station PFEIFFER EcoCube 80 for analyzing desorbed gases from solid samples at temperatures up to 1000°C and to estimate amount of these gases.

Creep machines for helikoid spring specimens (high sensitivity, low stresses)

Creep machines for helikoid spring specimens (high sensitivity, low stresses)

Contact person: RNDr. Luboš Kloc, CSc.

Two machines for creep experiments with high strain sensitivity at low stresses.

SATEC creep machines

SATEC creep machines

Contact person: Ing. Jiří Dvořák, Ph.D.

Eight creep machines for conventional tests of metallic materials up to 1000°C in air.

Creep machines - our own design

Creep machines - our own design

Contact person: Ing. Petr Dymáček, Ph.D.

35 creep machines of our own construction allowing tests up to 950°C and various loading modes.

In all tests - possibility of protective atmosphere: purified dry argon, hydrogen, nitrogen.

Creep machine for helicoid spring specimens

Creep machine for helicoid spring specimens

Contact person: RNDr. Luboš Kloc, CSc.

Two creep machines for high strain sensitivity tests at medium stresses.

Creep test system Zwick/Roell - Messphysik KAPPA LA spring 20kN with furnace MAYTEC up to 1400°C

Creep test system Zwick/Roell - Messphysik KAPPA LA spring 20kN with furnace MAYTEC up to 1400°C

Contact person: Ing. Petr Dymáček, Ph.D.

Creep test system Zwick/Roell - Messphysik KAPPA LA spring 20kN, with furnace MAYTEC up to 1400 °C, testing in Ar protective atmosphere or vacuum.

Creep test system Zwick/Roell - Messphysik KAPPA LA spring 50kN, with furnace MAYTEC up to 1200 °C

Creep test system Zwick/Roell - Messphysik KAPPA LA spring 50kN, with furnace MAYTEC up to 1200 °C

Contact person: Ing. Petr Dymáček, Ph.D.

Creep test system Zwick/Roell - Messphysik KAPPA LA spring 50kN, with furnace MAYTEC up to 1200 °C, testing in air and Ar protective atmosphere

Differential Scanning Calorimeter NETZSCH Phoenix 204 F1

Differential Scanning Calorimeter NETZSCH Phoenix 204 F1

Contact person:

Low-temperature DSC enables the studies of phase transformations, measurments of enthalpy and heat capacityat temperatures from -180°C.

Creep machine for torsion tests

Creep machine for torsion tests

Contact person: RNDr. Luboš Kloc, CSc.

Creep machine for torsion tests with high strain sensitivity at low stresses.

Electrochemical hydrogen charging system

Electrochemical hydrogen charging system

Contact person:

The system consists from a double jacked electroanalytical cell Biologic, source-measure unit Keysight U2722A and circulation water bath Witeg WCR-8. The systém is useful for cathodic hydrogen charging of metalic samples in a tempered electrolyte.

HANNA HI-5521-02 Research Grade pH/ORP/EC/TDS/Resistivity/Salinity Bench Meter

HANNA HI-5521-02 Research Grade pH/ORP/EC/TDS/Resistivity/Salinity Bench Meter

Contact person:

This Multifunctional Instrument Enables Measurement of pH, Redox Potential, Electric Conductivity, Electric resistivity, Total Dissolved Solids and Salinity in water based solutions. This instrument can be connected to a PC and make time-record of measurments.

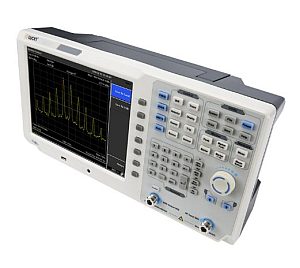

High voltage breakdown tester GW Instek GPT-9802

High voltage breakdown tester GW Instek GPT-9802

Contact person:

This high voltage generator allows insulators characteristics and safety of electric devices testing.

Portable Calibration Furnace ISOTECH Pegasus

Portable Calibration Furnace ISOTECH Pegasus

Contact person: Ing. Jaromír Bernovský

Furnace for thermocouple calibration

3D printer Prusa SL1

3D printer Prusa SL1

Contact person: doc. Mgr. Dinara Sobola, Ph.D.

This 3D printer is based on SLA technology. It means a resin is cured with UV light layer by layer. In our laboratory we often use that for making sample holders useful for grinding or electrochemical experiments..

Automatic demineralised water machine

Automatic demineralised water machine

Contact person:

Fully automatic machine to produce demineralised water. Process is based on reverse osmosis and filtration with mixture of catex and anex.

Digital indicator SYLVAC NANO

Digital indicator SYLVAC NANO

Contact person:

Digital indicator useful for metallographic preparation of samples with high precision thickness requirement (for small-punch testing samples or TEM foils).

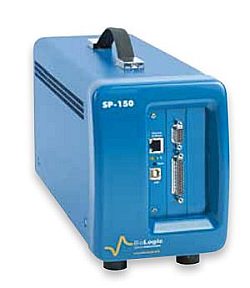

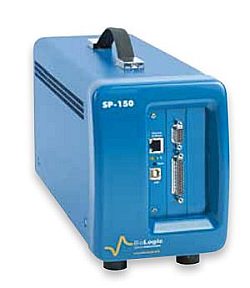

Potentiostat Biologic SP-150

Potentiostat Biologic SP-150

Contact person:

Research grade electrochemical workstation equipped with EIS useful for cathodic hydrogenation, a anodization (nanotubes growing) and corrosion measurement.

all publications

Advanced High-temperature Materials Group

| Head | Ing. Ivo Kuběna, Ph.D. |

| [javascript protected email address] | |

| Phone number | +420 532 290 371 |

| Room | 219 |

Experimental and theoretical investigations are carried out in attempt to improve understanding of the relationship between the microstructure and high-temperature mechanical properties of advanced materials for extending the service temperatures in creep related applications. Current research is concentrated on the microstructural evolution and understanding the underlying creep deformation and fracture processes to gain insight to facilitate further development of improved materials. Special attention is given to the methods of prediction creeplife exploted materials.

Following topics have been studied in last five years:

- creep strenght of advanced martensitic 9-12%Cr steels,

- microstructure, properties and application of gamma – TiAl intermetallics,

- creep properties of zirconium alloys for cladding tubes,

- high-temperature properties of nickel-based superalloys,

- design and creep behaviour of metal matrix composites (MMCs),

- creep behaviour of ultrafine-grained metals and alloys processed by equal channel angular pressing (ECAP),

- modelling of microstructural processes and high-temperature properties in advanced materials,

- creep damage assessment and lifetime prediction methods.

Researchers

| Name | Phone numbers | Rooms | |

|---|---|---|---|

| prof. RNDr. Antonín Dlouhý, CSc. | +420 532 290 412 | 205 | [javascript protected email address] |

| Ing. Jiří Dvořák, Ph.D. | +420 532 290 397 | 251 | [javascript protected email address] |

| Ing. Petr Dymáček, Ph.D. | +420 532 290 411 | 204 | [javascript protected email address] |

| Mgr. Milan Heczko, Ph.D. | +420 532 290 341 | 116a | [javascript protected email address] |

| Ing. Milan Jarý, Ph.D. | +420 532 290 405 | 252 | [javascript protected email address] |

| RNDr. Luboš Kloc, CSc. | +420 532 290 441 | 310 | [javascript protected email address] |

| Ing. Petr Král, Ph.D. | +420 532 290 368 | 202 | [javascript protected email address] |

| Mgr. Marie Kvapilová, Ph.D. | +420 532 290 374 | 221a | [javascript protected email address] |

| Ing. Natália Králová, Ph.D. | +420 532 290 373 | 221 | [javascript protected email address] |

| prof. Ing. Václav Sklenička, DrSc. | +420 532 290 454 | 418 | [javascript protected email address] |

| RNDr. Jiří Svoboda, CSc., DSc. | +420 532 290 407 | 201 | [javascript protected email address] |

| Mgr. Tomáš Záležák, Ph.D. | +420 532 290 372 | 258 | [javascript protected email address] |

Postdocs

| Name | Phone numbers | Rooms | |

|---|---|---|---|

| Ing. Denisa Bártková, Ph.D. | +420 532 290 373 | 221 | [javascript protected email address] |

| Ing. Petr Bořil, Ph.D. | +420 532 290 371 | 219 | [javascript protected email address] |

Phd students

| Name | Phone numbers | Rooms | |

|---|---|---|---|

| Ing. Markéta Gálíková | +420 532 290 384 | 207 | [javascript protected email address] |

Technicians

| Name | Phone numbers | Rooms | |

|---|---|---|---|

| Ing. Jaromír Bernovský | +420 532 290 396 | 258a | [javascript protected email address] |

| Ing. Rudolf Peňáz | +420 532 290 442 | 309 | [javascript protected email address] |

| Ing. Miroslav Vitula | +420 532 290 404 | 253 | [javascript protected email address] |

| Project number | Name | Investigator |

|---|---|---|

| 25-15579S | Experimental and numerical research on relaxation of residual stresses induced by selective laser melting | Ing. Petr Dymáček, Ph.D. |

| P1.14 | High Performance components consisting of new generation ODS Materials (ODS-Components) | RNDr. Jiří Svoboda, CSc., DSc. |

| 101091621 | Advanced modelling and characterization for power semiconductor materials and technologies (AddMorePower) | RNDr. Jiří Svoboda, CSc., DSc. |

| FW06010572 | Development of testing machine (SPC 1300 DLS) for very high temperature (up to 1300°C) creep testing of miniature specimens according to EN 10371 – Metallic materials - small punch test method | Ing. Petr Dymáček, Ph.D. |

| P2.2 | High strength hydrogen resistant alloys – Part II (HyResMat II) | RNDr. Jiří Svoboda, CSc., DSc. |

| Project number | Name | Investigator |

|---|---|---|

| 23-06167S | High-temperature damage mechanisms in Ni-based superalloy fabricated by laser powder bed fusion | Ing. Ivo Kuběna, Ph.D. |

| P1.9 | Development and implementation of a materials acceleration platform at MCL (MCacceL) | RNDr. Jiří Svoboda, CSc., DSc. |

| P2.22 | Damage evolution in lead-free solder joints – advanced characterization and modelling approaches (ECOsolder) | RNDr. Jiří Svoboda, CSc., DSc. |

| CZ.01.1.02/0.0/0.0/20_321/0024947 | Research and Development of Heat Treatment in Energy-saving Furnaces for Shape Stability of Bearing Components | RNDr. Jiří Svoboda, CSc., DSc. |

| TITSSUJB938 | Metoda hodnocení integrity tlakové nádoby reaktoru JE VVER-1000 při těžké havárii spojené s tavením jaderného paliva. | Ing. Petr Dymáček, Ph.D. |

| 8J21AT002 | Impact of hydrogen on structural and functional properties of NiTi shape memory alloys | prof. RNDr. Antonín Dlouhý, CSc. |

| 21-02203X | Beyond properties of current top performance alloys | RNDr. Jiří Svoboda, CSc., DSc. |

| TK03020089 | Acoustic Emission Diagnostics of Pipeline Systems Damage designed for Residual Life Estimation | Ing. Jiří Dvořák, Ph.D. |

| NU20-08-00149 | Multicentric evaluation of hypersensitivity reactions in patients indicated for total joint replacement including evaluation of the reasons for reimplanting | prof. RNDr. Antonín Dlouhý, CSc. |

| 20-11321S | Influence of microstructure and surface treatments on hydrogen intake in bio-compatible alloys | prof. RNDr. Antonín Dlouhý, CSc. |

| 20-14450J | The damage evolution in ultrafine-grained metals and alloys under fatigue and creep loading | Ing. Jiří Dvořák, Ph.D. |

| 20-14237S | Microstructure and functional properties refinement by dopant distribution in transparent ceramics - combined experimental and theoretical approach | RNDr. Jiří Svoboda, CSc., DSc. |

| 19-18725S | Influence of microstructure on creep mechanisms in advanced heat resistant steels | Ing. Petr Král, Ph.D. |

| COMET K2 A1.23 | Fundamentals and tools for integrated computational modeling and experimental characterization of materials in the atomic to micrometer scale range (A1.23) | RNDr. Jiří Svoboda, CSc., DSc. |

| 17-01641S | Improvement of Properties and Complex Characterization of New Generation Fe-Al-O Based Oxide Precipitation Hardened Steels | RNDr. Jiří Svoboda, CSc., DSc. |

| TH02020477 | Experimental research and modelling of modified fuel cladding under LOCA conditions | prof. Ing. Václav Sklenička, DrSc. |

| TH02020691 | Experimental investigation and mathematical simulation of behaviour of the modified cladding tubes of nuclear fuel under storage conditions | RNDr. Luboš Kloc, CSc. |

| FV10699 | Research and development of nickel and cobalt based superalloys castings | prof. Ing. Václav Sklenička, DrSc. |

| 16-09518S | Creep damage mechanisms in advanced tungsten modified 9%Cr ferritic steel | prof. Ing. Václav Sklenička, DrSc. |

| 15-21394S | Creep deformation of new grade UNS S31035 austenitic steel including transient effects | RNDr. Luboš Kloc, CSc. |

| 15-16336S | Interstitial impurities in NiTi-based shape memory alloys | prof. RNDr. Antonín Dlouhý, CSc. |

| 15-06390S | Utilization of theoretical and experimental approaches to sintering for tailoring the microstructure and properties of advanced ceramic materials | RNDr. Jiří Svoboda, CSc., DSc. |

| A1.17 | Inverse process chain modeling for Al-castings and induction heat treated steel rods | RNDr. Jiří Svoboda, CSc., DSc. |

| 14-22834S | Phase Stability and Plasticity in Medium-to-High-Entropy Alloys | prof. RNDr. Antonín Dlouhý, CSc. |

| 14-24252S | Preparation and Optimization of Creep Resistant Submicron-Structured Composite with Fe-Al Matrix and Al2O3 Particles | RNDr. Jiří Svoboda, CSc., DSc. |

| A2.26 | Development of new-generation ODS alloys and ODS composites | RNDr. Jiří Svoboda, CSc., DSc. |

| FP7-309916-2 | Z-phase strengthened steels for ultra-supercritical power plants | RNDr. Jiří Svoboda, CSc., DSc. |

| P108/12/1452 | Optimizing the high temperature mechanical properties of iron aluminides of Fe3Al type with carbide forming elements | Ing. Ferdinand Dobeš, DrSc. |

| CZ.1.07/2.4.00/31.0046 | NETME Working - Innovation and Technology Transfer in Mechanical Engineering | RNDr. Jiří Svoboda, CSc., DSc. |

| TA02011025 | Creep and oxidation properties of E110 cladding tube under LOCA temperature transient | prof. Ing. Václav Sklenička, DrSc. |

| 8/12 AS CR - RAS | Microstructural features and mechanical properties of nanocrystalline titanium | Ing. Jiří Dvořák, Ph.D. |

| 9/12 AS CR - RAS | Investigation of creep and fatigue behaviour of metallic nanomaterials processed by severe plastic deformation | Mgr. Marie Kvapilová, Ph.D. |

| TA02010260 | Research of materials changes occurring in advanced steels used for construction and reconstruction of pipelines in power and chemical plants | prof. Ing. Václav Sklenička, DrSc. |

| FR-TI4/406 | Research of the Influence of Orbital Head Welding Technology of Thick-Walled Tubes/Pipes on their Long-Therm Lifetime in Condition of Modern Power Plants Service | prof. Ing. Václav Sklenička, DrSc. |

| Energy.2009.6.1.1. | Material component performance driven solutions for long-term efficiency increase in ultra supercritical power plants (MACPLUS) | prof. Ing. Václav Sklenička, DrSc. |

| A1.9 | The impact of atomic trapping on diffusion and phase transformation kinetics | RNDr. Jiří Svoboda, CSc., DSc. |

| P204-10-1784 | Modelling of diffusional phase transformations in multi-component systems with multiple stoichiometric phases | RNDr. Jiří Svoboda, CSc., DSc. |

| A6.14 | Service security of welded high-strength pressurized pipelines | RNDr. Jiří Svoboda, CSc., DSc. |

| P108-10-1781 | The role of stress state and vacancy supersaturation at the formation of binary hollow nanoparticles | RNDr. Jiří Svoboda, CSc., DSc. |

| OC10029 | Thermodynamic modelling of microstructure evolution in nanocomposites | RNDr. Jiří Svoboda, CSc., DSc. |

| P108/10/P469 | Influence of initial crystallographic orientation on creep behaviour of SPD materials | Ing. Petr Král, Ph.D. |

| 202/09/2073 | Deformation mechanisms of in-situ composite materials | prof. RNDr. Antonín Dlouhý, CSc. |

| 106/09/1913 | Martensitic transformations in NiTi alloys | prof. RNDr. Antonín Dlouhý, CSc. |

| IAA 200410801 | Numerical modeling of small punch tests on miniaturized specimens from advanced steels for reliable life-time estimation | Ing. Petr Dymáček, Ph.D. |

| 106/08/1238 | Investigation of possibilities of strengthening of iron-aluminides-based alloys by second-phase particles | Ing. Ferdinand Dobeš, DrSc. |

| KJB200410801 | Study of nano-structure materials consolidated from powder compacts by ECAP technique | Ing. Jiří Dvořák, Ph.D. |

| IAA200410701 | Transient Effects in Creep at Conditions Leading to Very Low Strain Rates | RNDr. Luboš Kloc, CSc. |

| GA106/07/0762 | Structure, properties and metallurgy of near-gamma TiAl alloys | prof. RNDr. Antonín Dlouhý, CSc. |

| IAA200410601 | Modelování kinetiky difúzních fázových transformací v pevných látkách | RNDr. Jiří Svoboda, CSc., DSc. |

| 2A-1TP1/057 | Solutions of materials and technological innovations of new generation power and chemical plants operating at high temperatures | prof. Ing. Václav Sklenička, DrSc. |

| 106/06/1354 | Effect of reinforcement-matrix interface on the strength and thermal properties of Mg-Al-Ca alloy composites | RNDr. Karel Milička, DrSc. |

| AV0Z20410507-I052 | Numerical simulations of small punch tests on miniature specimens for determination of residual and guaranteed life of heat resistant steels. | Ing. Petr Dymáček, Ph.D. |

| GA106/05/0409 | The analysis of mechanisms and factors influencing the creep resistance of perspective iron aluminides on the basis of Fe3Al and FeAl | Ing. Ferdinand Dobeš, DrSc. |

| FT-TA2/038 | Materials solutions of new generation of heat transfer facilities for power and chemical engineering | prof. Ing. Václav Sklenička, DrSc. |

| 1-2005 | Modelling of diffusive and massive phase transformations in solids | RNDr. Jiří Svoboda, CSc., DSc. |

| COST 563.001, No. 1P05OC007 | Microstructural evolution and creep strength in advanced power plant steels | prof. Ing. Václav Sklenička, DrSc. |

| 1P05OC006 | High strain sensitivity creep testing techniques for validation of creep constitutive models | RNDr. Luboš Kloc, CSc. |

| 106/05/0918 | NiTi Shape Memory Alloys and Their Processing-Structure-Transformation Relationship | prof. RNDr. Antonín Dlouhý, CSc. |

| SP-16 | Characterization of the precipitate microstucture | RNDr. Jiří Svoboda, CSc., DSc. |

| 106/04/0853 | Thermal and Strain Cycles in the TiAl Intermetallic Casting - Ceramic Shell Mould System | prof. RNDr. Antonín Dlouhý, CSc. |

| GA106/03/1353 | Analysis of heat resistance of weldments in energetic facilities by means of small punch tests on thin discs | RNDr. Karel Milička, DrSc. |

| IAA2041301 | Creep processes in ultrafine-grained metals and alloys processed by the ECAP technique | prof. Ing. Václav Sklenička, DrSc. |

| GA106/03/0843 | Microprocesses of plastic deformation in light metals based advanced alloys and composites at elevated temperatures | RNDr. Karel Milička, DrSc. |

| IAA2041202 | Alternative methods of the activation analysis in creep | Ing. Ferdinand Dobeš, DrSc. |

| A106/02/0608 | Long-term microstructural stability and creep behaviour of advanced 9-12%Cr steels | prof. Ing. Václav Sklenička, DrSc. |

| OC 526.60 | A Numerically Based Optimization of a Near-gamma TiAl Precision Casting Process | prof. RNDr. Antonín Dlouhý, CSc. |

| GA106/02/0274 | Small punch creep tests of mechanically alloyed aluminium alloys | Ing. Ferdinand Dobeš, DrSc. |

| IAA2041203 | Thermally activated deformation and internal stress in alloys and composites | RNDr. Karel Milička, DrSc. |

| A2041101 | Creep of a priori Brittle Materials for High Temperature Applications at Very Low Creep Rates | RNDr. Luboš Kloc, CSc. |

| 106/99/1649 | High-temperature properties of Ni-Cr-W-C systém | prof. Ing. Václav Sklenička, DrSc. |

| COST 522 | Creep data prediction for advanced engineering alloys | prof. Ing. Václav Sklenička, DrSc. |

Creep test machines of our own design with direct load

Creep test machines of our own design with direct loadContact person: Ing. Petr Dymáček, Ph.D.

6 creep test machines of own design with direct load for performing of tensile creep tests in constant load mode

Creep test system Zwick/Roell KAPPA DS 50 kN, with furnace up to 1200 °C

Creep test system Zwick/Roell KAPPA DS 50 kN, with furnace up to 1200 °CContact person: Ing. Petr Dymáček, Ph.D.

Creep test system Zwick/Roell KAPPA DS 50 kN, with furnace up to 1200 °C, testing in air

Thermal Desorption Spectroscopy Instrument

Thermal Desorption Spectroscopy InstrumentContact person:

The instrument is consists of a horizontal furnace CLASSIC 4011T, a quadrupole mass spectrometer PFEIFFER PrismaPro QM 250 M1 and a vakuum station PFEIFFER EcoCube 80 for analyzing desorbed gases from solid samples at temperatures up to 1000°C and to estimate amount of these gases.

Creep machines for helikoid spring specimens (high sensitivity, low stresses)

Creep machines for helikoid spring specimens (high sensitivity, low stresses)Contact person: RNDr. Luboš Kloc, CSc.

Two machines for creep experiments with high strain sensitivity at low stresses.

SATEC creep machines

SATEC creep machinesContact person: Ing. Jiří Dvořák, Ph.D.

Eight creep machines for conventional tests of metallic materials up to 1000°C in air.

Creep machines - our own design

Creep machines - our own designContact person: Ing. Petr Dymáček, Ph.D.

35 creep machines of our own construction allowing tests up to 950°C and various loading modes.

In all tests - possibility of protective atmosphere: purified dry argon, hydrogen, nitrogen.

Creep machine for helicoid spring specimens

Creep machine for helicoid spring specimensContact person: RNDr. Luboš Kloc, CSc.

Two creep machines for high strain sensitivity tests at medium stresses.

Creep test system Zwick/Roell - Messphysik KAPPA LA spring 20kN with furnace MAYTEC up to 1400°C

Creep test system Zwick/Roell - Messphysik KAPPA LA spring 20kN with furnace MAYTEC up to 1400°CContact person: Ing. Petr Dymáček, Ph.D.

Creep test system Zwick/Roell - Messphysik KAPPA LA spring 20kN, with furnace MAYTEC up to 1400 °C, testing in Ar protective atmosphere or vacuum.

Creep test system Zwick/Roell - Messphysik KAPPA LA spring 50kN, with furnace MAYTEC up to 1200 °C

Creep test system Zwick/Roell - Messphysik KAPPA LA spring 50kN, with furnace MAYTEC up to 1200 °CContact person: Ing. Petr Dymáček, Ph.D.

Creep test system Zwick/Roell - Messphysik KAPPA LA spring 50kN, with furnace MAYTEC up to 1200 °C, testing in air and Ar protective atmosphere

Differential Scanning Calorimeter NETZSCH Phoenix 204 F1

Differential Scanning Calorimeter NETZSCH Phoenix 204 F1Contact person:

Low-temperature DSC enables the studies of phase transformations, measurments of enthalpy and heat capacityat temperatures from -180°C.

Creep machine for torsion tests

Creep machine for torsion testsContact person: RNDr. Luboš Kloc, CSc.

Creep machine for torsion tests with high strain sensitivity at low stresses.

Electrochemical hydrogen charging system

Electrochemical hydrogen charging systemContact person:

The system consists from a double jacked electroanalytical cell Biologic, source-measure unit Keysight U2722A and circulation water bath Witeg WCR-8. The systém is useful for cathodic hydrogen charging of metalic samples in a tempered electrolyte.

HANNA HI-5521-02 Research Grade pH/ORP/EC/TDS/Resistivity/Salinity Bench Meter

HANNA HI-5521-02 Research Grade pH/ORP/EC/TDS/Resistivity/Salinity Bench MeterContact person:

This Multifunctional Instrument Enables Measurement of pH, Redox Potential, Electric Conductivity, Electric resistivity, Total Dissolved Solids and Salinity in water based solutions. This instrument can be connected to a PC and make time-record of measurments.

High voltage breakdown tester GW Instek GPT-9802

High voltage breakdown tester GW Instek GPT-9802Contact person:

This high voltage generator allows insulators characteristics and safety of electric devices testing.

Portable Calibration Furnace ISOTECH Pegasus

Portable Calibration Furnace ISOTECH PegasusContact person: Ing. Jaromír Bernovský

Furnace for thermocouple calibration

3D printer Prusa SL1

3D printer Prusa SL1Contact person: doc. Mgr. Dinara Sobola, Ph.D.

This 3D printer is based on SLA technology. It means a resin is cured with UV light layer by layer. In our laboratory we often use that for making sample holders useful for grinding or electrochemical experiments..

Automatic demineralised water machine

Automatic demineralised water machineContact person:

Fully automatic machine to produce demineralised water. Process is based on reverse osmosis and filtration with mixture of catex and anex.

Digital indicator SYLVAC NANO

Digital indicator SYLVAC NANOContact person:

Digital indicator useful for metallographic preparation of samples with high precision thickness requirement (for small-punch testing samples or TEM foils).

Potentiostat Biologic SP-150

Potentiostat Biologic SP-150Contact person:

Research grade electrochemical workstation equipped with EIS useful for cathodic hydrogenation, a anodization (nanotubes growing) and corrosion measurement.

all publications