Institute of Physics of Materials AS CR, v. v. i. > Laboratories > Laboratories of fracture properties of materials

Brillant 220 automatic / manual metallographic saw Metalco

Brillant 220 automatic / manual metallographic saw Metalco

Contact: Ing. Zdeněk Chlup, Ph.D.

Brillant-220 is an universal precision saw designed for manual and automatic precision cutting of very small and larger specimens.

Polishing machine Struers LaboPol 5 and 25

Polishing machine Struers LaboPol 5 and 25

Contact: Ing. Zdeněk Chlup, Ph.D.

One disc (LaboPol 5) and two discs (LaboPol 25) grinding and polishing machines for manual or semi-automatic (LaboForce 3 head + LaboDoser) preparation of materialographic specimens.

Electromechanical test system ZWICK Z250

Electromechanical test system ZWICK Z250

Contact: Ing. Zdeněk Balík

The universal test system enabling force loading up to 250 kN is mainly used for quasi-static testing of various loading modes like tensile, pressure, bend and fracture toughness testing for a wide range of materials especially for metals, polymers or possibly ceramics and theirs composites in a relatively wide temperature range.

Laboratory dryer BMT Venticell 22

Laboratory dryer BMT Venticell 22

Contact: Ing. Zdeněk Chlup, Ph.D.

Precise and fast laboratory dryer with a chamber volume of 22 litres up to a temperature of 250°C with forced air circulation for drying, heating and sterilization of materials in laboratories.

Planetary ball mill Fritsch Pulverisette 6

Planetary ball mill Fritsch Pulverisette 6

Contact: Ing. Hynek Hadraba, Ph.D.

Single-position mill for high-energy milling of powder materials under controlled atmosphere

Planetary ball mill Fritsch Pulverisette 4

Planetary ball mill Fritsch Pulverisette 4

Contact: Ing. Hynek Hadraba, Ph.D.

Two-position mill for high-energy milling of powder materials under controlled atmosphere

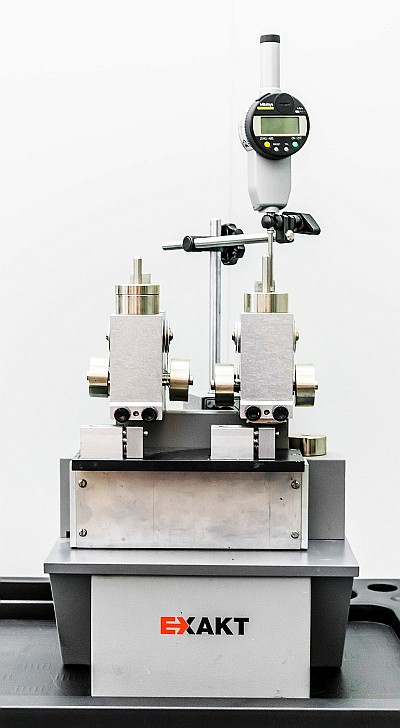

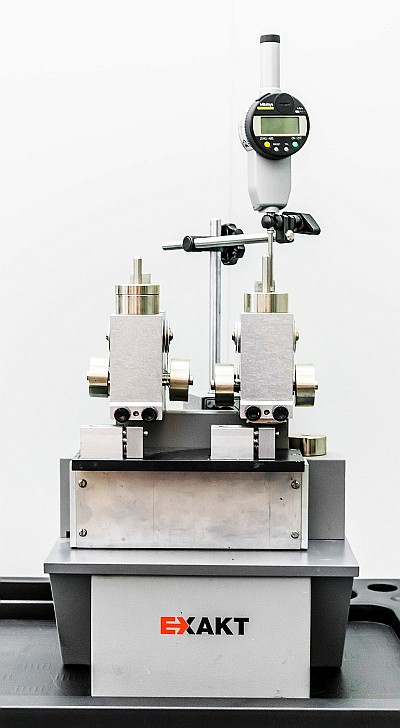

Razorblade notching machine EXAKT

Razorblade notching machine EXAKT

Contact: Ing. Zdeněk Chlup, Ph.D.

The machine enables semi-automatic preparation of V-notch into ceramic bending specimens according to the ČSN EN ISO 23146 standard. It has two positions of the sample clamping device, which enable the efficient preparation of two notches during one processing time. Adjustable cutting speed and variable load allow adjusting the V-notch production process for a given material.

Ultrasonic Flaw Detector EPOCH 650

Ultrasonic Flaw Detector EPOCH 650

Contact: Ing. Zdeněk Chlup, Ph.D.

A portable digital ultrasonic flaw detector can be used to detect internal material defects.

Universal nanomechanical testing machine Zwick ZHN

Universal nanomechanical testing machine Zwick ZHN

Contact: Dr. Ing. Filip Šiška, Ph.D.

The test machine is used for indentation, scratch, wear and compression tests of materials and surface layers at room temperatures. The maximal loading capacity is 2N. The machine is equipped with diamond tips of Vickers, Berkovich type, spherical with diameters of 20 and 50 μm and flat tips with diameters 5 and 100 μm.

Vibratory sieve shaker Fritsch Analysette 3 – Spartan

Vibratory sieve shaker Fritsch Analysette 3 – Spartan

Contact: Ing. Hynek Hadraba, Ph.D.

Vibratory sieve shaker for dividing powder materials into the required particle size.

3D multi-material printer CeraFab Multi 2M30

3D multi-material printer CeraFab Multi 2M30

Contact: Ing. Zdeněk Chlup, Ph.D.

It is a multi-material 3D printer designed for the development of new geometrically arranged structures and composites using the principle of photopolymerization. The Lithoz CeraFab Multi 2M30 printer can combine not only two types of ceramics in one layer, but also ceramics with metal or polymer.

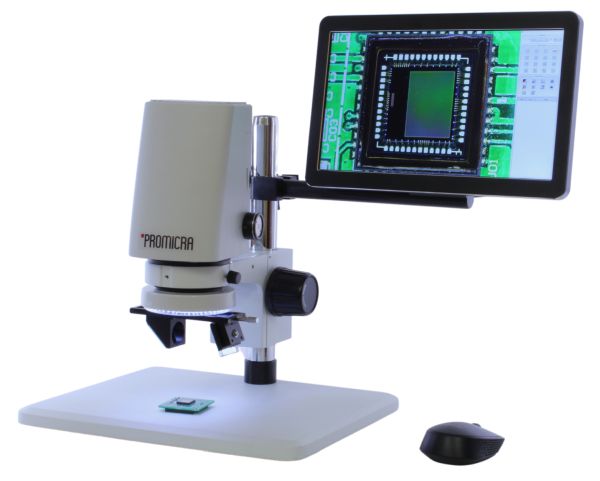

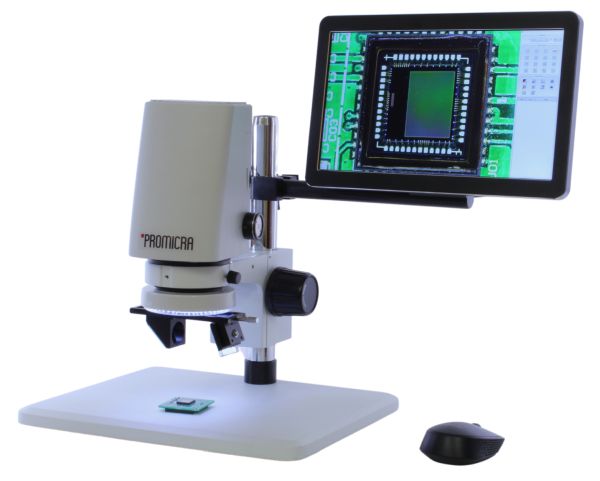

All-in-One 3D Digital Microscope PRO-7 3D

All-in-One 3D Digital Microscope PRO-7 3D

Contact: Ing. Zdeněk Chlup, Ph.D.

It is a compact device that integrates a 7:1 optical zoom microscope with a constant plane of sharpness, a Full HD digital camera, a built-in computer with measurement software, a circular LED illuminator and an integrated monitor.

Screw driven testing machine ZWICK Z50

Screw driven testing machine ZWICK Z50

Contact: Ing. Zdeněk Balík

A universal testing system predominately used for quasi-static tensile, compressive, bending experiments of polymers, metals, ceramic and their composites at wide range of temperatures.

Universal test system INSTRON 8862 with electromechanical actuator

Universal test system INSTRON 8862 with electromechanical actuator

Contact: Ing. Zdeněk Chlup, Ph.D.

A universal testing system predominately used for bending and compressive experiments of ceramic and ceramic composites at room temperatures.

High temperature impulse excitation technique IMCE HT1600

High temperature impulse excitation technique IMCE HT1600

Contact: Ing. Zdeněk Chlup, Ph.D.

The system allows obtaining temperature dependence of the elastic properties of the material by non-destructive impulse excitation method.

High temperature test system

High temperature test system

Contact: Ing. Zdeněk Chlup, Ph.D.

A test system is designed for testing at temperatures up to 1600°C. Tests of metals, ceramics and composites can be performed in vacuum or under a protective argon atmosphere.

Instrumented impact tester Zwick/Roell B5113.303 (50 J)

Instrumented impact tester Zwick/Roell B5113.303 (50 J)

Contact: Ing. Luděk Stratil, Ph.D.

Load measurement, different instrumented and non-instrumented pendulums from 0.5J up to 50J, dynamic tensile test adaptor. The fracture process can be monitored by high speed camera Olympus i-SPEED 3 with extreme low light sensitivity and up to 150,000 fps recoding.

Micro-testing machine MTS Tytron 250

Micro-testing machine MTS Tytron 250

Contact: Ing. Luděk Stratil, Ph.D.

Load cell up to ± 250 N, loading speed up to 0.5 m/s. Fixtures for tensile and three or four point bend test.

Screw driven testing machine ZWICK Z2.5 equipped with micro hardness head ZHU0.2 with optics

Screw driven testing machine ZWICK Z2.5 equipped with micro hardness head ZHU0.2 with optics

Contact: Ing. Hynek Hadraba, Ph.D.

Load cell of testing machine up to 2.5 kN. Micro hardness head equipped with instrumented Vickers, Knoop and universal micro-hardness test with load up to 200 N and position resolution 20 nm.

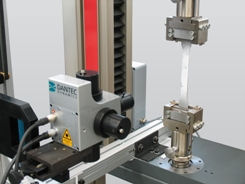

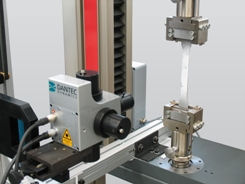

ESPI System Q-300 Dantec Dynamics

ESPI System Q-300 Dantec Dynamics

Contact: Ing. Zdeněk Chlup, Ph.D.

An Electronic Speckle Pattern Interferometry (ESPI) for high sensitive displacement and strain analysis.

Mortar grinder Fritsch Pulverisette 2

Mortar grinder Fritsch Pulverisette 2

Contact: Ing. Hynek Hadraba, Ph.D.

Mechanical mortar for milling and mixing powders.

UF55 universal oven Memmert

UF55 universal oven Memmert

Contact: Ing. Luca Bertolla, Ph.D.

Universal equipment suitable for drying, heating, aging, burn-in, and hardening.

Jacomex GP Campus glovebox

Jacomex GP Campus glovebox

Contact: Ing. Hynek Hadraba, Ph.D.

The stainless steel glovebox with glass protective shield allows work in an atmosphere of inert gases (Ar, He).

Sonopuls ultrasonic homogenizer Bandelin

Sonopuls ultrasonic homogenizer Bandelin

Contact: Ing. Luca Bertolla, Ph.D.

Sonopuls ultrasonic homogenizer generates high-performance ultrasound with high intensities and ultrasonic amplitudes, which are transferred into liquid media using the probe (metal tip).

Analytical balances DENVER Summit

Analytical balances DENVER Summit

Contact: Ing. Zdeněk Chlup, Ph.D.

The analytical balances Denver Summit are precious tool for weighting of small samples with the precision of 0.1 mg. The available density kit broadens their application to the density measurement.

Acoustic emission kit Dakel IPL

Acoustic emission kit Dakel IPL

Contact: Ing. Zdeněk Chlup, Ph.D.

for 4 channels continuous recording of AE signal with measuring and analysing software.

Laboratories of fracture properties of materials

Virtual tourTake a Tour |

| Determination of basic and fracture-mechanics properties of materials. |

Brillant 220 automatic / manual metallographic saw Metalco

Brillant 220 automatic / manual metallographic saw MetalcoContact: Ing. Zdeněk Chlup, Ph.D.

Brillant-220 is an universal precision saw designed for manual and automatic precision cutting of very small and larger specimens.

Polishing machine Struers LaboPol 5 and 25

Polishing machine Struers LaboPol 5 and 25Contact: Ing. Zdeněk Chlup, Ph.D.

One disc (LaboPol 5) and two discs (LaboPol 25) grinding and polishing machines for manual or semi-automatic (LaboForce 3 head + LaboDoser) preparation of materialographic specimens.

Electromechanical test system ZWICK Z250

Electromechanical test system ZWICK Z250Contact: Ing. Zdeněk Balík

The universal test system enabling force loading up to 250 kN is mainly used for quasi-static testing of various loading modes like tensile, pressure, bend and fracture toughness testing for a wide range of materials especially for metals, polymers or possibly ceramics and theirs composites in a relatively wide temperature range.

Laboratory dryer BMT Venticell 22

Laboratory dryer BMT Venticell 22Contact: Ing. Zdeněk Chlup, Ph.D.

Precise and fast laboratory dryer with a chamber volume of 22 litres up to a temperature of 250°C with forced air circulation for drying, heating and sterilization of materials in laboratories.

Planetary ball mill Fritsch Pulverisette 6

Planetary ball mill Fritsch Pulverisette 6Contact: Ing. Hynek Hadraba, Ph.D.

Single-position mill for high-energy milling of powder materials under controlled atmosphere

Planetary ball mill Fritsch Pulverisette 4

Planetary ball mill Fritsch Pulverisette 4Contact: Ing. Hynek Hadraba, Ph.D.

Two-position mill for high-energy milling of powder materials under controlled atmosphere

Razorblade notching machine EXAKT

Razorblade notching machine EXAKTContact: Ing. Zdeněk Chlup, Ph.D.

The machine enables semi-automatic preparation of V-notch into ceramic bending specimens according to the ČSN EN ISO 23146 standard. It has two positions of the sample clamping device, which enable the efficient preparation of two notches during one processing time. Adjustable cutting speed and variable load allow adjusting the V-notch production process for a given material.

Ultrasonic Flaw Detector EPOCH 650

Ultrasonic Flaw Detector EPOCH 650Contact: Ing. Zdeněk Chlup, Ph.D.

A portable digital ultrasonic flaw detector can be used to detect internal material defects.

Universal nanomechanical testing machine Zwick ZHN

Universal nanomechanical testing machine Zwick ZHNContact: Dr. Ing. Filip Šiška, Ph.D.

The test machine is used for indentation, scratch, wear and compression tests of materials and surface layers at room temperatures. The maximal loading capacity is 2N. The machine is equipped with diamond tips of Vickers, Berkovich type, spherical with diameters of 20 and 50 μm and flat tips with diameters 5 and 100 μm.

Vibratory sieve shaker Fritsch Analysette 3 – Spartan

Vibratory sieve shaker Fritsch Analysette 3 – SpartanContact: Ing. Hynek Hadraba, Ph.D.

Vibratory sieve shaker for dividing powder materials into the required particle size.

3D multi-material printer CeraFab Multi 2M30

3D multi-material printer CeraFab Multi 2M30Contact: Ing. Zdeněk Chlup, Ph.D.

It is a multi-material 3D printer designed for the development of new geometrically arranged structures and composites using the principle of photopolymerization. The Lithoz CeraFab Multi 2M30 printer can combine not only two types of ceramics in one layer, but also ceramics with metal or polymer.

All-in-One 3D Digital Microscope PRO-7 3D

All-in-One 3D Digital Microscope PRO-7 3DContact: Ing. Zdeněk Chlup, Ph.D.

It is a compact device that integrates a 7:1 optical zoom microscope with a constant plane of sharpness, a Full HD digital camera, a built-in computer with measurement software, a circular LED illuminator and an integrated monitor.

Screw driven testing machine ZWICK Z50

Screw driven testing machine ZWICK Z50Contact: Ing. Zdeněk Balík

A universal testing system predominately used for quasi-static tensile, compressive, bending experiments of polymers, metals, ceramic and their composites at wide range of temperatures.

Universal test system INSTRON 8862 with electromechanical actuator

Universal test system INSTRON 8862 with electromechanical actuatorContact: Ing. Zdeněk Chlup, Ph.D.

A universal testing system predominately used for bending and compressive experiments of ceramic and ceramic composites at room temperatures.

High temperature impulse excitation technique IMCE HT1600

High temperature impulse excitation technique IMCE HT1600Contact: Ing. Zdeněk Chlup, Ph.D.

The system allows obtaining temperature dependence of the elastic properties of the material by non-destructive impulse excitation method.

High temperature test system

High temperature test systemContact: Ing. Zdeněk Chlup, Ph.D.

A test system is designed for testing at temperatures up to 1600°C. Tests of metals, ceramics and composites can be performed in vacuum or under a protective argon atmosphere.

Instrumented impact tester Zwick/Roell B5113.303 (50 J)

Instrumented impact tester Zwick/Roell B5113.303 (50 J)Contact: Ing. Luděk Stratil, Ph.D.

Load measurement, different instrumented and non-instrumented pendulums from 0.5J up to 50J, dynamic tensile test adaptor. The fracture process can be monitored by high speed camera Olympus i-SPEED 3 with extreme low light sensitivity and up to 150,000 fps recoding.

Micro-testing machine MTS Tytron 250

Micro-testing machine MTS Tytron 250Contact: Ing. Luděk Stratil, Ph.D.

Load cell up to ± 250 N, loading speed up to 0.5 m/s. Fixtures for tensile and three or four point bend test.

Screw driven testing machine ZWICK Z2.5 equipped with micro hardness head ZHU0.2 with optics

Screw driven testing machine ZWICK Z2.5 equipped with micro hardness head ZHU0.2 with opticsContact: Ing. Hynek Hadraba, Ph.D.

Load cell of testing machine up to 2.5 kN. Micro hardness head equipped with instrumented Vickers, Knoop and universal micro-hardness test with load up to 200 N and position resolution 20 nm.

ESPI System Q-300 Dantec Dynamics

ESPI System Q-300 Dantec DynamicsContact: Ing. Zdeněk Chlup, Ph.D.

An Electronic Speckle Pattern Interferometry (ESPI) for high sensitive displacement and strain analysis.

Mortar grinder Fritsch Pulverisette 2

Mortar grinder Fritsch Pulverisette 2Contact: Ing. Hynek Hadraba, Ph.D.

Mechanical mortar for milling and mixing powders.

UF55 universal oven Memmert

UF55 universal oven MemmertContact: Ing. Luca Bertolla, Ph.D.

Universal equipment suitable for drying, heating, aging, burn-in, and hardening.

Jacomex GP Campus glovebox

Jacomex GP Campus gloveboxContact: Ing. Hynek Hadraba, Ph.D.

The stainless steel glovebox with glass protective shield allows work in an atmosphere of inert gases (Ar, He).

Sonopuls ultrasonic homogenizer Bandelin

Sonopuls ultrasonic homogenizer BandelinContact: Ing. Luca Bertolla, Ph.D.

Sonopuls ultrasonic homogenizer generates high-performance ultrasound with high intensities and ultrasonic amplitudes, which are transferred into liquid media using the probe (metal tip).

Analytical balances DENVER Summit

Analytical balances DENVER SummitContact: Ing. Zdeněk Chlup, Ph.D.

The analytical balances Denver Summit are precious tool for weighting of small samples with the precision of 0.1 mg. The available density kit broadens their application to the density measurement.

Acoustic emission kit Dakel IPL

Acoustic emission kit Dakel IPLContact: Ing. Zdeněk Chlup, Ph.D.

for 4 channels continuous recording of AE signal with measuring and analysing software.