Institute of Physics of Materials AS CR, v. v. i. > Groups > Brittle Fracture Group

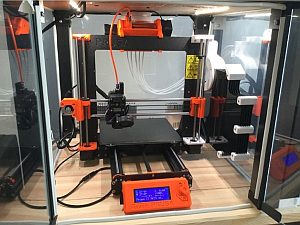

3D printer Průša I3 MK3

3D printer Průša I3 MK3

Contact person: Ing. Hynek Hadraba, Ph.D.

3D printer for printing objects by hot printing method from thermoplastic string - filament.

Brillant 220 automatic / manual metallographic saw Metalco

Brillant 220 automatic / manual metallographic saw Metalco

Contact person: Ing. Zdeněk Chlup, Ph.D.

Brillant-220 is an universal precision saw designed for manual and automatic precision cutting of very small and larger specimens.

Polishing machine Struers LaboPol 5 and 25

Polishing machine Struers LaboPol 5 and 25

Contact person: Ing. Zdeněk Chlup, Ph.D.

One disc (LaboPol 5) and two discs (LaboPol 25) grinding and polishing machines for manual or semi-automatic (LaboForce 3 head + LaboDoser) preparation of materialographic specimens.

Electromechanical test system ZWICK Z250

Electromechanical test system ZWICK Z250

Contact person: Ing. Zdeněk Balík

The universal test system enabling force loading up to 250 kN is mainly used for quasi-static testing of various loading modes like tensile, pressure, bend and fracture toughness testing for a wide range of materials especially for metals, polymers or possibly ceramics and theirs composites in a relatively wide temperature range.

Laboratory dryer BMT Venticell 22

Laboratory dryer BMT Venticell 22

Contact person: Ing. Zdeněk Chlup, Ph.D.

Precise and fast laboratory dryer with a chamber volume of 22 litres up to a temperature of 250°C with forced air circulation for drying, heating and sterilization of materials in laboratories.

Planetary ball mill Fritsch Pulverisette 6

Planetary ball mill Fritsch Pulverisette 6

Contact person: Ing. Hynek Hadraba, Ph.D.

Single-position mill for high-energy milling of powder materials under controlled atmosphere

Planetary ball mill Fritsch Pulverisette 4

Planetary ball mill Fritsch Pulverisette 4

Contact person: Ing. Hynek Hadraba, Ph.D.

Two-position mill for high-energy milling of powder materials under controlled atmosphere

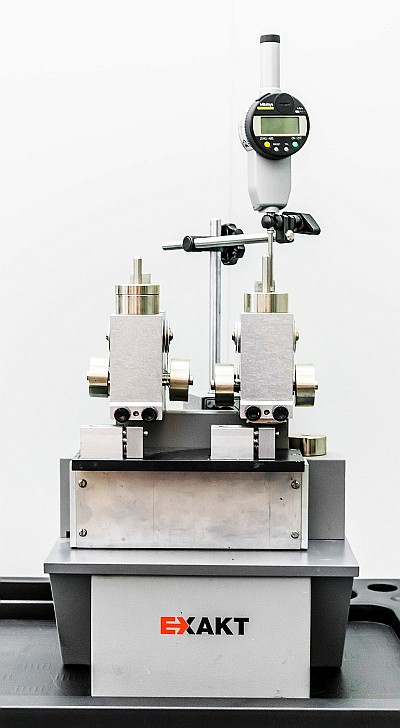

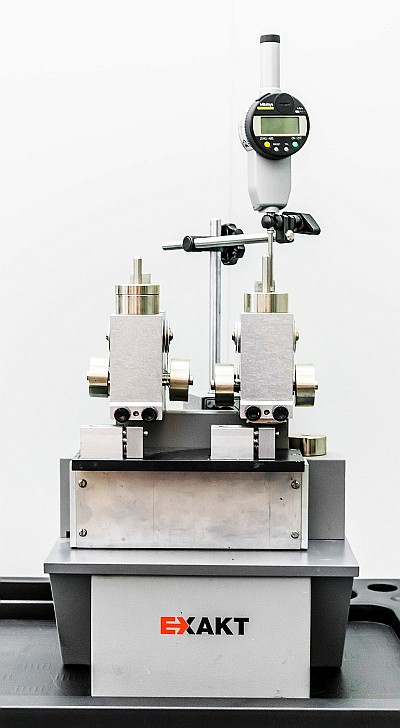

Razorblade notching machine EXAKT

Razorblade notching machine EXAKT

Contact person: Ing. Zdeněk Chlup, Ph.D.

The machine enables semi-automatic preparation of V-notch into ceramic bending specimens according to the ČSN EN ISO 23146 standard. It has two positions of the sample clamping device, which enable the efficient preparation of two notches during one processing time. Adjustable cutting speed and variable load allow adjusting the V-notch production process for a given material.

Ultrasonic Flaw Detector EPOCH 650

Ultrasonic Flaw Detector EPOCH 650

Contact person: Ing. Zdeněk Chlup, Ph.D.

A portable digital ultrasonic flaw detector can be used to detect internal material defects.

Universal nanomechanical testing machine Zwick ZHN

Universal nanomechanical testing machine Zwick ZHN

Contact person: Dr. Ing. Filip Šiška, Ph.D.

The test machine is used for indentation, scratch, wear and compression tests of materials and surface layers at room temperatures. The maximal loading capacity is 2N. The machine is equipped with diamond tips of Vickers, Berkovich type, spherical with diameters of 20 and 50 μm and flat tips with diameters 5 and 100 μm.

Vibratory sieve shaker Fritsch Analysette 3 – Spartan

Vibratory sieve shaker Fritsch Analysette 3 – Spartan

Contact person: Ing. Hynek Hadraba, Ph.D.

Vibratory sieve shaker for dividing powder materials into the required particle size.

3D multi-material printer CeraFab Multi 2M30

3D multi-material printer CeraFab Multi 2M30

Contact person: Ing. Zdeněk Chlup, Ph.D.

It is a multi-material 3D printer designed for the development of new geometrically arranged structures and composites using the principle of photopolymerization. The Lithoz CeraFab Multi 2M30 printer can combine not only two types of ceramics in one layer, but also ceramics with metal or polymer.

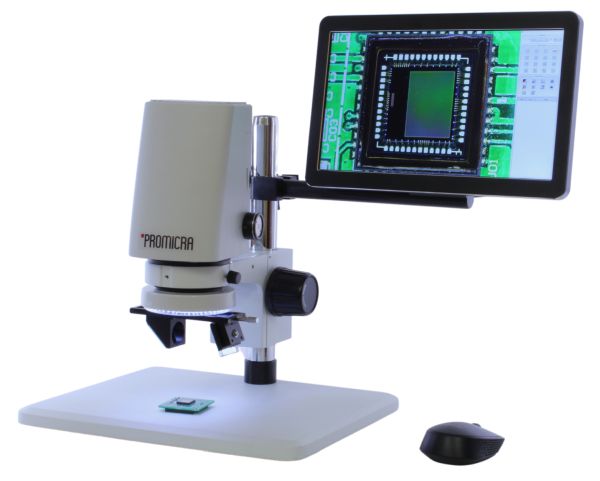

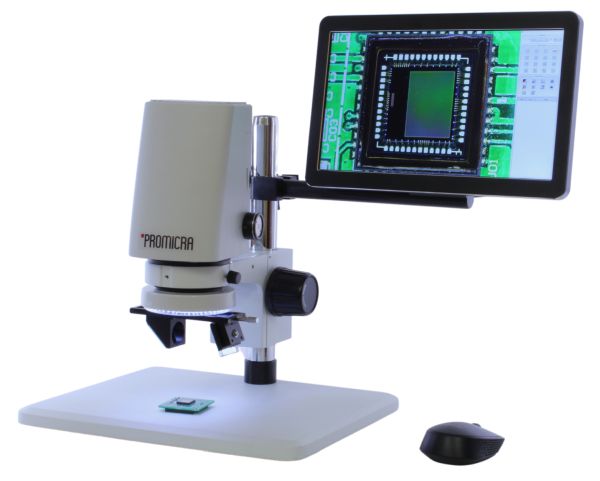

All-in-One 3D Digital Microscope PRO-7 3D

All-in-One 3D Digital Microscope PRO-7 3D

Contact person: Ing. Zdeněk Chlup, Ph.D.

It is a compact device that integrates a 7:1 optical zoom microscope with a constant plane of sharpness, a Full HD digital camera, a built-in computer with measurement software, a circular LED illuminator and an integrated monitor.

Screw driven testing machine ZWICK Z50

Screw driven testing machine ZWICK Z50

Contact person: Ing. Zdeněk Balík

A universal testing system predominately used for quasi-static tensile, compressive, bending experiments of polymers, metals, ceramic and their composites at wide range of temperatures.

Universal test system INSTRON 8862 with electromechanical actuator

Universal test system INSTRON 8862 with electromechanical actuator

Contact person: Ing. Zdeněk Chlup, Ph.D.

A universal testing system predominately used for bending and compressive experiments of ceramic and ceramic composites at room temperatures.

High temperature impulse excitation technique IMCE HT1600

High temperature impulse excitation technique IMCE HT1600

Contact person: Ing. Zdeněk Chlup, Ph.D.

The system allows obtaining temperature dependence of the elastic properties of the material by non-destructive impulse excitation method.

High temperature test system

High temperature test system

Contact person: Ing. Zdeněk Chlup, Ph.D.

A test system is designed for testing at temperatures up to 1600°C. Tests of metals, ceramics and composites can be performed in vacuum or under a protective argon atmosphere.

Instrumented impact tester Zwick/Roell B5113.303 (50 J)

Instrumented impact tester Zwick/Roell B5113.303 (50 J)

Contact person: Ing. Luděk Stratil, Ph.D.

Load measurement, different instrumented and non-instrumented pendulums from 0.5J up to 50J, dynamic tensile test adaptor. The fracture process can be monitored by high speed camera Olympus i-SPEED 3 with extreme low light sensitivity and up to 150,000 fps recoding.

Olympus LEXT OLS3100 confocal microscope with AFM modul

Olympus LEXT OLS3100 confocal microscope with AFM modul

Contact person: Ing. Hynek Hadraba, Ph.D.

Microscope for documentation of microstructure and fracture surfaces, 3D reconstruction of surfaces and their further geometrical analysis.

Micro-testing machine MTS Tytron 250

Micro-testing machine MTS Tytron 250

Contact person: Ing. Luděk Stratil, Ph.D.

Load cell up to ± 250 N, loading speed up to 0.5 m/s. Fixtures for tensile and three or four point bend test.

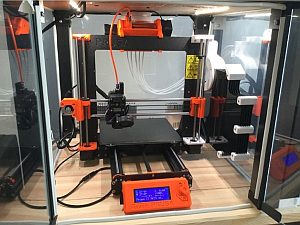

3D Printer Prusa i3 MKS3+ & MMU2S (Prusa Research)

3D Printer Prusa i3 MKS3+ & MMU2S (Prusa Research)

Contact person: Ing. Hynek Hadraba, Ph.D.

The Prusa i3 MK3S+ 3D printer is the successor to the successful MK2 model. The main advantages of the MK3S+ include a redesigned extruder, a range of sensors and smart features.

3D printer Prusa SL1

3D printer Prusa SL1

Contact person: Ing. Hynek Hadraba, Ph.D.

This 3D printer is based on SLA technology. It means a resin is cured with UV light layer by layer. In our laboratory we often use that for making sample holders useful for grinding or electrochemical experiments..

Screw driven testing machine ZWICK Z2.5 equipped with micro hardness head ZHU0.2 with optics

Screw driven testing machine ZWICK Z2.5 equipped with micro hardness head ZHU0.2 with optics

Contact person: Ing. Hynek Hadraba, Ph.D.

Load cell of testing machine up to 2.5 kN. Micro hardness head equipped with instrumented Vickers, Knoop and universal micro-hardness test with load up to 200 N and position resolution 20 nm.

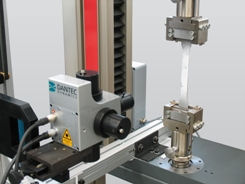

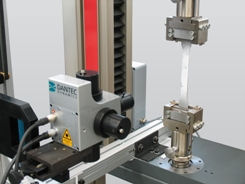

ESPI System Q-300 Dantec Dynamics

ESPI System Q-300 Dantec Dynamics

Contact person: Ing. Zdeněk Chlup, Ph.D.

An Electronic Speckle Pattern Interferometry (ESPI) for high sensitive displacement and strain analysis.

Mortar grinder Fritsch Pulverisette 2

Mortar grinder Fritsch Pulverisette 2

Contact person: Ing. Hynek Hadraba, Ph.D.

Mechanical mortar for milling and mixing powders.

UF55 universal oven Memmert

UF55 universal oven Memmert

Contact person: Ing. Luca Bertolla, Ph.D.

Universal equipment suitable for drying, heating, aging, burn-in, and hardening.

INSTRON E3000 with linear motor technology

INSTRON E3000 with linear motor technology

Contact person: prof. Ing. Pavel Hutař, Ph.D.

Electrodynamic testing instrument INSTRON with closed control loop for static or dynamic testing from very small to high frequencies (200 Hz and more). Maximal load is of ±3000 N for dynamic testing and ±2100 N for static testing. The system is equipped with temperature controlled chamber INSTRON 3119-605 with a temperature range from -100°C in LN2 atmosphere (-70 °C in CO2) to 350 °C and the internal dimensions of 485×240×230 mm.

Jacomex GP Campus glovebox

Jacomex GP Campus glovebox

Contact person: Ing. Hynek Hadraba, Ph.D.

The stainless steel glovebox with glass protective shield allows work in an atmosphere of inert gases (Ar, He).

Sonopuls ultrasonic homogenizer Bandelin

Sonopuls ultrasonic homogenizer Bandelin

Contact person: Ing. Luca Bertolla, Ph.D.

Sonopuls ultrasonic homogenizer generates high-performance ultrasound with high intensities and ultrasonic amplitudes, which are transferred into liquid media using the probe (metal tip).

Analytical balances DENVER Summit

Analytical balances DENVER Summit

Contact person: Ing. Zdeněk Chlup, Ph.D.

The analytical balances Denver Summit are precious tool for weighting of small samples with the precision of 0.1 mg. The available density kit broadens their application to the density measurement.

Acoustic emission kit Dakel IPL

Acoustic emission kit Dakel IPL

Contact person: Ing. Zdeněk Chlup, Ph.D.

for 4 channels continuous recording of AE signal with measuring and analysing software.

Precise linear saw Buehler ISOMET 5000

Precise linear saw Buehler ISOMET 5000

Contact person: Ing. Zdeněk Chlup, Ph.D.

The cutting machine allows precious sectioning of very hard materials using diamond blades of various dimensions.

all publications

Brittle Fracture Group

| Head | Ing. Zdeněk Chlup, Ph.D. |

| [javascript protected email address] | |

| Phone number | +420 532 290 335, +420 532 290 314, +420 532 290 308 |

| Room | 128a, 5, Zwick lab. |

The Brittle Fracture Group, which has been a part of the Institute of Physics of Materials since its foundation, has been led from the beginning by doc. Ing. Miloslav Holzmann, CSc., who has investigated the transition region of brittle fracture of steels in detail using experimental fracture mechanics. The next group leader since 1990 was prof. Ing. Ivo Dlouhý, CSc., who expanded the research area of the group to include advanced ceramic and ceramic-based composite materials, which required a complete modernization of the experimental equipment to enable research at higher temperatures under lower loads.

The original focus of the group on the characterisation of the brittle fracture behaviour of iron alloys has now been significantly extended to the development, preparation, and subsequent evaluation of the properties of metallic, ceramic, and polymeric materials and their composites. The group uses theoretical principles, numerical simulations, experimental material preparation and advanced characterization to design new materials with desired properties. Understanding the fundamental physical mechanisms of deformation and failure under various loading conditions (tension, compression, bending and shear) at temperatures from -196 °C to 1500 °C is an integral part of the research, both for materials developed at the IPM and for materials from collaborating institutions or commercial entities. Targeted research for industrial partners is also an integral part of the group's activities.

Basic research areas of the group:

Design of new materials

Development of new materials

Study of (micro)mechanisms and phenomena

Experimental fracture mechanics

Areas of targeted research of the group

Short video presentation "Future of glass-ceramic materials"

The original focus of the group on the characterisation of the brittle fracture behaviour of iron alloys has now been significantly extended to the development, preparation, and subsequent evaluation of the properties of metallic, ceramic, and polymeric materials and their composites. The group uses theoretical principles, numerical simulations, experimental material preparation and advanced characterization to design new materials with desired properties. Understanding the fundamental physical mechanisms of deformation and failure under various loading conditions (tension, compression, bending and shear) at temperatures from -196 °C to 1500 °C is an integral part of the research, both for materials developed at the IPM and for materials from collaborating institutions or commercial entities. Targeted research for industrial partners is also an integral part of the group's activities.

Basic research areas of the group:

Design of new materials

- Multicomponent materials (high entropy alloys, carbides, and borides, etc.)

- Heterostructure (meta)materials

- Multifunctional composites (especially based on ceramics)

Development of new materials

- Preparation of metal and ceramic materials using mechanical alloying

- Preparation of geopolymer composite materials

- Preparation of nanostructured components, for example, graphene, by exfoliation technology

- Preparation of materials by hydrothermal consolidation

Study of (micro)mechanisms and phenomena

- Deformation and fracture phenomena in the structure under different loading conditions

- Experimental and theoretical study of the initiation, growth, and interaction of twins

- Material joints and their influence on deformation and fracture processes

- Interface effects in composite materials

Experimental fracture mechanics

- Static and dynamic fracture mechanical characteristics (fracture toughness, transit curve, J-da curve, etc.)

- Transferability of fracture mechanics data obtained from small volume specimens

- Fractographic analysis of fracture surfaces (metals, ceramics, and glass)

Areas of targeted research of the group

- Failure analysis in industrial applications including the design of corrective actions

- Characterization of physical and mechanical properties at temperatures from -196°C to 1500°C

- Support in the development of material models for numerical simulations

- Design of quality control procedures and setting of their parameters

Short video presentation "Future of glass-ceramic materials"

Researchers

| Name | Phone numbers | Rooms | |

|---|---|---|---|

| Ing. Luca Bertolla, Ph.D. | +420 532 290 415 | 208 | [javascript protected email address] |

| prof. Ing. Ivo Dlouhý, CSc. | +420 532 290 342 | 125 | [javascript protected email address] |

| Ing. Hynek Hadraba, Ph.D. | +420 532 290 369 | 127 | [javascript protected email address] |

| Ing. Luděk Stratil, Ph.D. | +420 532 290 365 | 126 | [javascript protected email address] |

| Dr. Ing. Filip Šiška, Ph.D. | +420 532 290 365 | 126 | [javascript protected email address] |

Technicians

| Name | Phone numbers | Rooms | |

|---|---|---|---|

| Ing. Zdeněk Balík | +420 532 290 314 | 5 | [javascript protected email address] |

| Ing. Pavel Čupera | +420 532 290 314 | 5 | [javascript protected email address] |

| Radek Ponížil | +420 532 290 364 | 109 | [javascript protected email address] |

| Bc. Radek Vácha | +420 532 290 364 | 109 | [javascript protected email address] |

Diploma students

| Name | Phone numbers | Rooms | |

|---|---|---|---|

| Radoslav Maňak | +420 532 290 336 | 128b | [javascript protected email address] |

Bachelor students

| Name | Phone numbers | Rooms | |

|---|---|---|---|

| Pavel Franek | +420 532 290 415 | 208 | [javascript protected email address] |

Student

| Name | Phone numbers | Rooms | |

|---|---|---|---|

| Dominik Marván | +420 532 290 336 | 128b | [javascript protected email address] |

| Project number | Name | Investigator |

|---|---|---|

| GA25-16210S | Twinning manipulation by altering the local microstructural conditions in magnesium alloys | Dr. Ing. Filip Šiška, Ph.D. |

| 4000144907/24/NL/AR | SteeLs improved by Oxides and Nitrides dispersion for launchers applications (SLON) | doc. Ing. Jan Klusák, Ph.D. |

| 24-12763S | Targeted microstructure manipulation for additive shaping of ODS alloys | Ing. Hynek Hadraba, Ph.D. |

| Project number | Name | Investigator |

|---|---|---|

| 4000138900/22/NL/GP/gg | Characterisation of Thermal and Mechanical Performance of SIM Cryostat Straps (CRYSA) | doc. Ing. Jan Klusák, Ph.D. |

| LUASK22219 | Development of new joining methods for high entropy ceramics | prof. Ing. Ivo Dlouhý, CSc. |

| 21-24805S | Tailoring of interfaces in lead-free ferroelectric-dielecric composites to enhance their electromechanical properties | Ing. Zdeněk Chlup, Ph.D. |

| 20-20873S | Development of High Temperature Liquid Metal Resistant ODS Steels for Fission/Fusion Application | Ing. Hynek Hadraba, Ph.D. |

| CZ.02.1.01/0.0/0.0/16_025/0007304 | Architectured materials designed for additive manufacturing (ArMAdit) | Ing. Hynek Hadraba, Ph.D. |

| 18-07140S | Multiscale analysis of twin-microstructure interactions in HCP metals and alloys | Dr. Ing. Filip Šiška, Ph.D. |

| 17-23964S | Dispersion strengthened high entropy alloys for extreme conditions | Ing. Hynek Hadraba, Ph.D. |

| 17-12546S | Fundamental aspects of partial pyrolysis of hybrid composites with polysiloxane matrix precursors | Ing. Zdeněk Chlup, Ph.D. |

| 17-13573S | Architectured metallic materials designed for cold spray kinetization | prof. Ing. Ivo Dlouhý, CSc. |

| 17-08153S | Novel material architectures for SMART piezoceramic electromechanical converters | Ing. Zdeněk Chlup, Ph.D. |

| MSM100411601 | Transferability issues in ductile to brittle transition and ductile regime | Ing. Luděk Stratil, Ph.D. |

| GrInHy - H2020 | GrInHy: Green Industrial Hydrogen via reversible high-temperature electrolysis | prof. Ing. Ivo Dlouhý, CSc. |

| CoACH - H2020 (MSCA-ITN) | CoACH: Advanced glasses, Composites And Ceramics for High growth Industries (European training network - ETN) | prof. Ing. Ivo Dlouhý, CSc. |

| GJ15-21292Y | Current perspectives of ferroelectric domain interfaces | Dr. Ing. Filip Šiška, Ph.D. |

| GA14-11234S | Experimental evaluation and computational modeling of ceramic foams response to mechanical loading | prof. Ing. Ivo Dlouhý, CSc. |

| GA14-25246S | Advanced ODS steels for application in heavy metal melts | Ing. Hynek Hadraba, Ph.D. |

| 7AMB14SK154 | Progressive soft magnetic materials based multicomponent alloys | Ing. Hynek Hadraba, Ph.D. |

| 7AMB14SK155 | Study of mechanical and fracture properties of composites reinforced nanoceramic boron nitride nanotubes | prof. Ing. Ivo Dlouhý, CSc. |

| WP12-MAT-01-ODSFS-01-01/IPP.CR/BS | EFDA - Production and characterization of laboratory-scale batches of nano-structured ODSFS | Ing. Hynek Hadraba, Ph.D. |

| 263476 | RoLiCer - Enhanced reliability and lifetime of ceramic components through multi-scale modelling of degradation and damage | Ing. Zdeněk Chlup, Ph.D. |

| FP7-PEOPLE-2010-ITN | Glass and Ceramic Composites for High Technology Applications – Initial Training Networks | prof. Ing. Ivo Dlouhý, CSc. |

| GAP108/11/1644 | Fracture mechanics characteristics of the interface of low toughness materials | Ing. Zdeněk Chlup, Ph.D. |

| GAP107/10/0361 | Microstructural design of high toughness materials | prof. Ing. Ivo Dlouhý, CSc. |

| GAP108/10/0466 | Fracture behaviour prediction based on quantification of local material response | Ing. Hynek Hadraba, Ph.D. |

| EFDA | Study of the micro-mechanisms of cleavage fracture of 14% Cr ODS ferritic steels | Ing. Hynek Hadraba, Ph.D. |

| ME 10117 | Development of new TiAl intermetallics with improved mechanical properties through the control of the microstructure of thermomechanical treatment | prof. Ing. Ivo Dlouhý, CSc. |

| CZ.1.07/2.4.00/12.0030 | Mechanical Engineering Cooperative Network | prof. Ing. Ivo Dlouhý, CSc. |

| CZ.1.07/2.3.00/09.0228 | Complex System for Attracting, Education and Continuing Involment of Talented Individuals to Research Centers of AS CR and FME BUT | prof. Ing. Ivo Dlouhý, CSc. |

| M100410902 | Fracture behaviour of ceramic-ceramic and metal-ceramic interface in laminate structures | Ing. Zdeněk Chlup, Ph.D. |

| GA101/09/1821 | Mechanical and fracture properties of multilayered ceramic/ceramic and ceramic/metal materials with graded layers | prof. Ing. Ivo Dlouhý, CSc. |

| CZ.1.05/2.1.00/01.0002 | NETME centre - New Technologies for Engineering - Division of Advanced Metallic Materials (AMM) | prof. Ing. Ivo Dlouhý, CSc. |

| GD106/09/H035 | Multiscale Design of Advanced Materials | prof. Ing. Ivo Dlouhý, CSc. |

| GA106/09/1101 | Development of new matrix types based on pyrolysed resins for composites reinforced with ceramic fibres | Ing. Zdeněk Chlup, Ph.D. |

| GA101/08/1304 | Simulation of the brittle damage and fracture of heteroneneous materials | Ing. Vladislav Kozák, CSc. |

| EFDA | Study of the micro-mechanisms of cleavage fracture of 14% Cr ODS | Ing. Hynek Hadraba, Ph.D. |

| MEB060714 | Influence of Contact Stresses on Results of the Ball on the Three Balls Test | Ing. Zdeněk Chlup, Ph.D. |

| GA106/08/1397 | Effect of ultrafine particles dispersion on cleavage fracture of chromium steels | Ing. Hynek Hadraba, Ph.D. |

| ME08051 | NUCLEATION OF CONE CRACK AT BIAXIAL BEND TEST | Ing. Zdeněk Chlup, Ph.D. |

| IPP-CR UT7 DEGR | Euratom | prof. Ing. Ivo Dlouhý, CSc. |

| GA106/07/0762 | Structure, properties and metallurgy of near-gamma TiAl alloys | prof. RNDr. Antonín Dlouhý, CSc. |

| GA106/06/0646 | The micromechanics of self-affine fractal cracks in brittle materials | prof. Ing. Ivo Dlouhý, CSc. |

| GA106/06/0724 | Micro-structurally induced shielding effects in toughening of ceramic matrix composites | prof. Ing. Ivo Dlouhý, CSc. |

| ME854 (1016/2006-32) | Synergetic effects of microstructure and testing conditions on ceramics fracture resistance assessment | Ing. Zdeněk Chlup, Ph.D. |

| AV0Z20410507 | Physical properties of advanced materials in relation to their microstructure and processing | doc. RNDr. Petr Lukáš, CSc., dr. h. c. |

| 2005-23 | Corrections of statistical size effects on fracture toughness characteristics of structural ceramics | Ing. Zdeněk Chlup, Ph.D. |

| GA106/05/0495 | Impact response and dynamic failure of brittle materials | prof. Ing. Ivo Dlouhý, CSc. |

| GA101/05/0493 | Damage prediction of structural materials using cohesive models | Ing. Vladislav Kozák, CSc. |

| 106/05/P119 | Fracture toughness scatter in ceramics and brittle matrix composites at higher temperatures | Ing. Zdeněk Chlup, Ph.D. |

| GD106/05/H008 | Multiscale Design of Advanced Materials I | prof. Ing. Ivo Dlouhý, CSc. |

| 1QS200410502 | Properties of engineering materials under development applicable in the near future in traffic, medicine and power generating industry | prof. RNDr. Ludvík Kunz, CSc., dr. h. c. |

| IAA200410502 | The scaling role of damage inhomogeneity in brittle failure | prof. Ing. Ivo Dlouhý, CSc. |

| ME 491 | Properties degradation in thermally loaded glass matrix composites | prof. Ing. Ivo Dlouhý, CSc. |

| GA106/02/0745 | Bainitic cast steel for dynamically loaded components | Ing. Vladislav Kozák, CSc. |

| GA101/02/0683 | Crack/microcrack behaviour in selected brittle matrix composites | prof. Ing. Ivo Dlouhý, CSc. |

| GA106/01/0342 | Physical metallurgy aspect of fatigue damage of engineering parts made from steels multiaxially stressed by cycling loading | prof. Ing. Ivo Dlouhý, CSc. |

| IBS2041001 | Degradation of properties and lifetime assessment of engineering materials under mechanical loading | prof. RNDr. Ludvík Kunz, CSc., dr. h. c. |

| IAA2041003 | Brittle fracture micromechanics and toughness scaling models | prof. Ing. Ivo Dlouhý, CSc. |

| GA101/00/0170 | The transferability of fracture toughness characteristics from point a view of integrity of components with defects | Ing. Vladislav Kozák, CSc. |

| IAC2041011 | Statistical aspects of constraint at brittle fracture initiation | prof. Ing. Ivo Dlouhý, CSc. |

| AV0Z2041904 | Behavior and properties of metallic and non-metallic materials in relation to their structure, research on processes leading to degradation of material quality | doc. RNDr. Petr Lukáš, CSc., dr. h. c. |

| ME 303 | Fracture Resistance of Steels for Containers of Spent Nuclear Fuel | prof. Ing. Ivo Dlouhý, CSc. |

| ME 312 | Damage development in thermally shocked fibre reinforced borosilicate glass matrix composite | prof. Ing. Ivo Dlouhý, CSc. |

| GA106/98/0079 | Physical metallurgy aspects of the intergranular fracture damage of the structural steels | Ing. Vladislav Kozák, CSc. |

| OC 517.20 | Micromechanical aspects of brittle fracture initiation with respect to impurity effects | prof. Ing. Ivo Dlouhý, CSc. |

| IAA2041701 | The role of local constraint and strain rate in failure micromechanisms of duplex steels | prof. Ing. Ivo Dlouhý, CSc. |

| GV101/96/K264 | Limit states of failure in advanced structural materials assessed by means of unconventional test methods | prof. Ing. Ivo Dlouhý, CSc. |

3D printer Průša I3 MK3

3D printer Průša I3 MK3Contact person: Ing. Hynek Hadraba, Ph.D.

3D printer for printing objects by hot printing method from thermoplastic string - filament.

Brillant 220 automatic / manual metallographic saw Metalco

Brillant 220 automatic / manual metallographic saw MetalcoContact person: Ing. Zdeněk Chlup, Ph.D.

Brillant-220 is an universal precision saw designed for manual and automatic precision cutting of very small and larger specimens.

Polishing machine Struers LaboPol 5 and 25

Polishing machine Struers LaboPol 5 and 25Contact person: Ing. Zdeněk Chlup, Ph.D.

One disc (LaboPol 5) and two discs (LaboPol 25) grinding and polishing machines for manual or semi-automatic (LaboForce 3 head + LaboDoser) preparation of materialographic specimens.

Electromechanical test system ZWICK Z250

Electromechanical test system ZWICK Z250Contact person: Ing. Zdeněk Balík

The universal test system enabling force loading up to 250 kN is mainly used for quasi-static testing of various loading modes like tensile, pressure, bend and fracture toughness testing for a wide range of materials especially for metals, polymers or possibly ceramics and theirs composites in a relatively wide temperature range.

Laboratory dryer BMT Venticell 22

Laboratory dryer BMT Venticell 22Contact person: Ing. Zdeněk Chlup, Ph.D.

Precise and fast laboratory dryer with a chamber volume of 22 litres up to a temperature of 250°C with forced air circulation for drying, heating and sterilization of materials in laboratories.

Planetary ball mill Fritsch Pulverisette 6

Planetary ball mill Fritsch Pulverisette 6Contact person: Ing. Hynek Hadraba, Ph.D.

Single-position mill for high-energy milling of powder materials under controlled atmosphere

Planetary ball mill Fritsch Pulverisette 4

Planetary ball mill Fritsch Pulverisette 4Contact person: Ing. Hynek Hadraba, Ph.D.

Two-position mill for high-energy milling of powder materials under controlled atmosphere

Razorblade notching machine EXAKT

Razorblade notching machine EXAKTContact person: Ing. Zdeněk Chlup, Ph.D.

The machine enables semi-automatic preparation of V-notch into ceramic bending specimens according to the ČSN EN ISO 23146 standard. It has two positions of the sample clamping device, which enable the efficient preparation of two notches during one processing time. Adjustable cutting speed and variable load allow adjusting the V-notch production process for a given material.

Ultrasonic Flaw Detector EPOCH 650

Ultrasonic Flaw Detector EPOCH 650Contact person: Ing. Zdeněk Chlup, Ph.D.

A portable digital ultrasonic flaw detector can be used to detect internal material defects.

Universal nanomechanical testing machine Zwick ZHN

Universal nanomechanical testing machine Zwick ZHNContact person: Dr. Ing. Filip Šiška, Ph.D.

The test machine is used for indentation, scratch, wear and compression tests of materials and surface layers at room temperatures. The maximal loading capacity is 2N. The machine is equipped with diamond tips of Vickers, Berkovich type, spherical with diameters of 20 and 50 μm and flat tips with diameters 5 and 100 μm.

Vibratory sieve shaker Fritsch Analysette 3 – Spartan

Vibratory sieve shaker Fritsch Analysette 3 – SpartanContact person: Ing. Hynek Hadraba, Ph.D.

Vibratory sieve shaker for dividing powder materials into the required particle size.

3D multi-material printer CeraFab Multi 2M30

3D multi-material printer CeraFab Multi 2M30Contact person: Ing. Zdeněk Chlup, Ph.D.

It is a multi-material 3D printer designed for the development of new geometrically arranged structures and composites using the principle of photopolymerization. The Lithoz CeraFab Multi 2M30 printer can combine not only two types of ceramics in one layer, but also ceramics with metal or polymer.

All-in-One 3D Digital Microscope PRO-7 3D

All-in-One 3D Digital Microscope PRO-7 3DContact person: Ing. Zdeněk Chlup, Ph.D.

It is a compact device that integrates a 7:1 optical zoom microscope with a constant plane of sharpness, a Full HD digital camera, a built-in computer with measurement software, a circular LED illuminator and an integrated monitor.

Screw driven testing machine ZWICK Z50

Screw driven testing machine ZWICK Z50Contact person: Ing. Zdeněk Balík

A universal testing system predominately used for quasi-static tensile, compressive, bending experiments of polymers, metals, ceramic and their composites at wide range of temperatures.

Universal test system INSTRON 8862 with electromechanical actuator

Universal test system INSTRON 8862 with electromechanical actuatorContact person: Ing. Zdeněk Chlup, Ph.D.

A universal testing system predominately used for bending and compressive experiments of ceramic and ceramic composites at room temperatures.

High temperature impulse excitation technique IMCE HT1600

High temperature impulse excitation technique IMCE HT1600Contact person: Ing. Zdeněk Chlup, Ph.D.

The system allows obtaining temperature dependence of the elastic properties of the material by non-destructive impulse excitation method.

High temperature test system

High temperature test systemContact person: Ing. Zdeněk Chlup, Ph.D.

A test system is designed for testing at temperatures up to 1600°C. Tests of metals, ceramics and composites can be performed in vacuum or under a protective argon atmosphere.

Instrumented impact tester Zwick/Roell B5113.303 (50 J)

Instrumented impact tester Zwick/Roell B5113.303 (50 J)Contact person: Ing. Luděk Stratil, Ph.D.

Load measurement, different instrumented and non-instrumented pendulums from 0.5J up to 50J, dynamic tensile test adaptor. The fracture process can be monitored by high speed camera Olympus i-SPEED 3 with extreme low light sensitivity and up to 150,000 fps recoding.

Olympus LEXT OLS3100 confocal microscope with AFM modul

Olympus LEXT OLS3100 confocal microscope with AFM modulContact person: Ing. Hynek Hadraba, Ph.D.

Microscope for documentation of microstructure and fracture surfaces, 3D reconstruction of surfaces and their further geometrical analysis.

Micro-testing machine MTS Tytron 250

Micro-testing machine MTS Tytron 250Contact person: Ing. Luděk Stratil, Ph.D.

Load cell up to ± 250 N, loading speed up to 0.5 m/s. Fixtures for tensile and three or four point bend test.

3D Printer Prusa i3 MKS3+ & MMU2S (Prusa Research)

3D Printer Prusa i3 MKS3+ & MMU2S (Prusa Research)Contact person: Ing. Hynek Hadraba, Ph.D.

The Prusa i3 MK3S+ 3D printer is the successor to the successful MK2 model. The main advantages of the MK3S+ include a redesigned extruder, a range of sensors and smart features.

3D printer Prusa SL1

3D printer Prusa SL1Contact person: Ing. Hynek Hadraba, Ph.D.

This 3D printer is based on SLA technology. It means a resin is cured with UV light layer by layer. In our laboratory we often use that for making sample holders useful for grinding or electrochemical experiments..

Screw driven testing machine ZWICK Z2.5 equipped with micro hardness head ZHU0.2 with optics

Screw driven testing machine ZWICK Z2.5 equipped with micro hardness head ZHU0.2 with opticsContact person: Ing. Hynek Hadraba, Ph.D.

Load cell of testing machine up to 2.5 kN. Micro hardness head equipped with instrumented Vickers, Knoop and universal micro-hardness test with load up to 200 N and position resolution 20 nm.

ESPI System Q-300 Dantec Dynamics

ESPI System Q-300 Dantec DynamicsContact person: Ing. Zdeněk Chlup, Ph.D.

An Electronic Speckle Pattern Interferometry (ESPI) for high sensitive displacement and strain analysis.

Mortar grinder Fritsch Pulverisette 2

Mortar grinder Fritsch Pulverisette 2Contact person: Ing. Hynek Hadraba, Ph.D.

Mechanical mortar for milling and mixing powders.

UF55 universal oven Memmert

UF55 universal oven MemmertContact person: Ing. Luca Bertolla, Ph.D.

Universal equipment suitable for drying, heating, aging, burn-in, and hardening.

INSTRON E3000 with linear motor technology

INSTRON E3000 with linear motor technologyContact person: prof. Ing. Pavel Hutař, Ph.D.

Electrodynamic testing instrument INSTRON with closed control loop for static or dynamic testing from very small to high frequencies (200 Hz and more). Maximal load is of ±3000 N for dynamic testing and ±2100 N for static testing. The system is equipped with temperature controlled chamber INSTRON 3119-605 with a temperature range from -100°C in LN2 atmosphere (-70 °C in CO2) to 350 °C and the internal dimensions of 485×240×230 mm.

Jacomex GP Campus glovebox

Jacomex GP Campus gloveboxContact person: Ing. Hynek Hadraba, Ph.D.

The stainless steel glovebox with glass protective shield allows work in an atmosphere of inert gases (Ar, He).

Sonopuls ultrasonic homogenizer Bandelin

Sonopuls ultrasonic homogenizer BandelinContact person: Ing. Luca Bertolla, Ph.D.

Sonopuls ultrasonic homogenizer generates high-performance ultrasound with high intensities and ultrasonic amplitudes, which are transferred into liquid media using the probe (metal tip).

Analytical balances DENVER Summit

Analytical balances DENVER SummitContact person: Ing. Zdeněk Chlup, Ph.D.

The analytical balances Denver Summit are precious tool for weighting of small samples with the precision of 0.1 mg. The available density kit broadens their application to the density measurement.

Acoustic emission kit Dakel IPL

Acoustic emission kit Dakel IPLContact person: Ing. Zdeněk Chlup, Ph.D.

for 4 channels continuous recording of AE signal with measuring and analysing software.

Precise linear saw Buehler ISOMET 5000

Precise linear saw Buehler ISOMET 5000Contact person: Ing. Zdeněk Chlup, Ph.D.

The cutting machine allows precious sectioning of very hard materials using diamond blades of various dimensions.

all publications