Institute of Physics of Materials AS CR, v. v. i. > Groups > Structure of Phases and Thermodynamics Group

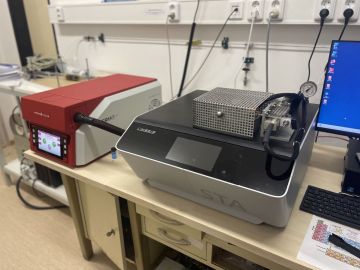

Device for simultaneous thermogravimetric and differential scanning calorimetrer analysis TGA/DSC-MS - Linesis PT1000 STA + QMS

Device for simultaneous thermogravimetric and differential scanning calorimetrer analysis TGA/DSC-MS - Linesis PT1000 STA + QMS

Contact person: Mgr. Ondřej Zobač, Ph.D.

Linesis PT1000 STA + Pfeiffer QMS - device for simultaneous thermogravimetric (TGA) and differential scanning calorimetrer (DSC) analysis, measures both, heat flow and weight change of a sample as a function of temperature or time under controlled atmosphere in the temperature range from RT to 1000 °C.

Differential Scanning Calorimeters, DSC 204 Phoenix and DSC 404 Pegasus by Netzsch

Differential Scanning Calorimeters, DSC 204 Phoenix and DSC 404 Pegasus by Netzsch

Contact person: RNDr. Aleš Kroupa, CSc.

The devices are used for the study of phase transformations in solids. DSC 204 is dedicated for low temperatures (-180 °C to 700 °C) and DCS 404 for high temperatures (to 1600 °C) range.

Setaram PCT PRO – E&E

Setaram PCT PRO – E&E

Contact person:

It is a fully automated Sievert’s instrument for measurement of gas sorption properties of materials.

Diamond Saw LECO VC-50

Diamond Saw LECO VC-50

Contact person:

The diamond saw is ideal for precise sectioning with minimal material deformation. It is suitable for sectioning of extremely hard materials - ceramics or metals.

IR FURNACE MILA-5000 ULVAC-RIKO, Inc.

IR FURNACE MILA-5000 ULVAC-RIKO, Inc.

Contact person: Ing. Lubomír Král, Ph.D.

The furnace MILA-5000 is characterized by extremely high rate of heating and rapid cooling of samples in vacuum, protective atmosphere or air.

Laboratory furnace LAC LT

Laboratory furnace LAC LT

Contact person: Ing. Lubomír Král, Ph.D.

The laboratory horizontal tube furnace with 40mm inside diameter of tube. It can be used up to temperature 1300°C.

Laboratory furnaces Classic

Laboratory furnaces Classic

Contact person: Ing. Lubomír Král, Ph.D.

Four horizontal tube furnaces with 40mm inside diameter of tube. They can be used up to temperature 1550°C. The temperature of sample is measured by thermocouple located near the sample. The temperature is stabilized within ± 1°C.

Microtom Leica RM2255

Microtom Leica RM2255

Contact person: Ing. Lubomír Král, Ph.D.

The rotary automated microtome which allows precise sectioning of radioactive samples with accurate specimen settings enables to set an exact zero point and angle of cutting.

Furnace Balzers VSG 02

Furnace Balzers VSG 02

Contact person:

The vacuum induction furnace with maximum charge of about 0.3 kg. The melting experiments can be conducted under vacuum or in a protective atmosphere.

Furnace MAM-1

Furnace MAM-1

Contact person: Ing. Lubomír Král, Ph.D.

The furnace MAM-1 is an arc melter designed for melting samples of approximate weight of 5-20 g under protective atmosphere Ar. The batch is melted on water cooled copper plate and it is possible also suction casting. The maximum melting temperature is 3500°C.

VC-50 saw LECO

VC-50 saw LECO

Contact person: Mgr. Ondřej Zobač, Ph.D.

Precision saw with the diamond cutting disc is suitable for cutting extremely hard materials.

all publications

Structure of Phases and Thermodynamics Group

| Head | Ing. Lubomír Král, Ph.D. |

| [javascript protected email address] | |

| Phone number | +420 532 290 427, +420 532 290 333, +420 532 290 334 |

| Room | 326, 121, 121 |

The research activity of the group is concentrated on:

- Experimental study of materials microstructure in connection with phase transformations

- Thermodynamic modelling of multicomponent alloy systems and kinetics of phase transformations

- Diffusion processes in solids and diffusion of hydrogen in selected functional materials

The first topic includes application of electron microscopy, both scanning and transmission, x-ray microanalysis including, to the study of microstructure of wide range of materials. The study of relations between existing phases, their morphology and mechanical properties on advanced structural materials (high-chromium steels, magnesium alloys, nickel alloys) should be mentioned among the recent results. The second topic is based on the application of existing thermodynamic models for calculations of thermodynamic equilibria and phase diagrams modelling in multicomponent systems, and simulation of diffusional processes. The third topic is focused on the study of volume diffusion and diffusion along high-diffusivity paths, on chemical diffusion under concentration gradients in multiphase materials and weldments, and on the study of transport properties of hydrogen in Mg-based materials for energy storage.

The topics solved by the group in the last five years:

- Advanced experimental and theoretical approaches to size-dependent phase diagrams of nanoalloys

- Thermal and phase stability of advanced thermoelectric materials

- Local microstructural changes induced by static and dynamic indentation in nanostructured and nanolaminate coatings

- The link between microstructure and creep behaviour of precipitate strengthened alloys processed by ECAP

- Mg diffusion in Mg-xNi and Mg-xNi-yX alloys with X = Zn, Ga, In, Si, Ge and Sn

- Study of surface of selected Ni alloys exposed to molted halide salts

- Carbon diffusion in carbon-supersaturated ferrite and austenite steels

- Kinetics of hydrogen desorption in Mg-base alloys modified by selected interstitial elements

Patents:

- Porous material for hydrogen storage and the methods of its preparation (Pat. No. 302464)

Researchers

| Name | Phone numbers | Rooms | |

|---|---|---|---|

| RNDr. Jiří Buršík, CSc., DSc. | +420 532 290 473 | 410 | [javascript protected email address] |

| Ing. Tomáš Káňa, Ph.D. | +420 532 290 423 | 320 | [javascript protected email address] |

| RNDr. Aleš Kroupa, CSc. | +420 532 290 467 | 415 | [javascript protected email address] |

| doc. Mgr. Jana Pavlů, Ph.D. | +420 532 290 400 | 310a | [javascript protected email address] |

| RNDr. Milan Svoboda, CSc. | +420 532 290 474 | 409 | [javascript protected email address] |

| Dr. Sanjay Gopal Ullattil | +420 532 290 422 | 319 | [javascript protected email address] |

| Ing. Adéla Zemanová, Ph.D. | +420 532 290 402 | 302 | [javascript protected email address] |

| Mgr. Ondřej Zobač, Ph.D. | +420 532 290 401 | 302 | [javascript protected email address] |

Postdocs

| Name | Phone numbers | Rooms | |

|---|---|---|---|

| Dr. Debika Devi Thongam | +420 532 290 424 | 322 | [javascript protected email address] |

Phd students

| Name | Phone numbers | Rooms | |

|---|---|---|---|

| Mgr. Ing. Sabina Kovaříková Oweis | +420 532 290 424 | 322 | [javascript protected email address] |

| Anjali Valadi Palliyalil | +420 532 290 424 | 322 | [javascript protected email address] |

Technicians

| Name | Phone numbers | Rooms | |

|---|---|---|---|

| Tomáš Lenc | +420 532 290 425 | 328 | [javascript protected email address] |

| Project number | Name | Investigator |

|---|---|---|

| CZ.02.01.01/00/22_008/0004631 | Materials and technologies for sustainable development (MATUR) | Ing. Petr Miarka, Ph.D. |

| Project number | Name | Investigator |

|---|---|---|

| 8J23AT006 | Synthesis and characterization of intermetallic supported nanoparticles. | Mgr. Ondřej Zobač, Ph.D. |

| 22-22187S | The theoretical and experimental study of the Al-Ge-Mg-Sn systems, application of novel 3rd generation data in CALPHAD-type thermodynamic modelling | RNDr. Aleš Kroupa, CSc. |

| 8J19AT011 | High entropy Half-Heusler thermoelectric materials with high efficiency | RNDr. Jiří Buršík, CSc., DSc. |

| 18-25660J | Complex theoretical and experimental phase diagram determinations of the advanced thermoelectric Ag-Pb-Sn-Te and Pb-Se-Sn-Te systems | RNDr. Aleš Kroupa, CSc. |

| 17-21683S | Kinetics of hydrogen storage in new complex hydrides of (Mg-Ni-M-S)-H type | |

| 17-15405S | Advanced experimental and theoretical approaches to size-dependent phase diagrams of nanoalloys | RNDr. Aleš Kroupa, CSc. |

| 17-12844S | Thermal and phase stability of advanced thermoelectric materials | RNDr. Jiří Buršík, CSc., DSc. |

| 15-17875S | Local microstructural changes induced by static and dynamic indentation in nanostructured and nanolaminate coatings | RNDr. Jiří Buršík, CSc., DSc. |

| 7AMB15AT002 | Spinodal Decomposition in Half-Heusler Alloys: A nanostructuring route towards high efficiency thermoelectric materials | RNDr. Jiří Buršík, CSc., DSc. |

| GA14-15576S | Complex study of phase diagrams of advanced metallic materials, combining ab initio and semiempirical modelling with experimental methods | RNDr. Aleš Kroupa, CSc. |

| LD11024 | Theoretical and experimental study of phase diagrams of nanoalloys | RNDr. Aleš Kroupa, CSc. |

| P108/11/0148 | Carbon diffusion in carbon-supersaturated ferrite and austenite steels | |

| P108/11/2260 | The link between microstructure and creep behaviour of precipitate strengthened alloys processed by ECAP | RNDr. Milan Svoboda, CSc. |

| P108/10/1908 | Thermodynamics of intermetallic phases using combined theoretical and experimental approach | RNDr. Aleš Kroupa, CSc. |

| 106/09/0814 | Desorption kinetics of hydrogen in Mg2Ni-H intermetallic modified by chosen interstitials | |

| 202/09/1013 | Nucleation and growth of oxygen precipitates in silicon | RNDr. Jiří Buršík, CSc., DSc. |

| 106/09/0700 | Thermodynamics and microstructure of environmentally friendly nanoparticle solders | RNDr. Jiří Buršík, CSc., DSc. |

| 106/08/1241 | Diffusion of iron in advanced Fe-base bulk metallic glasses | Ing. Ivo Stloukal, Ph.D. |

| OC08053 | Phase equilibria in Zn-Sn-X metallic systems for high-temperature lead-free solders | RNDr. Aleš Kroupa, CSc. |

| 106/07/0010 | Diffusion of hydrogen in alloys Mg-Ni modified by chosen elements that suppress the stability of hydrides | |

| COST MP0602 | HISOLD - Advanced Solder Materials for High Temperature Application | RNDr. Aleš Kroupa, CSc. |

| 106/07/1259 | Quasicrystalline phases in the Al-Pd-TM system | RNDr. Milan Svoboda, CSc. |

| 106/07/1078 | Theoretical and experimental investigations of thermodynamic properties in transition metal based intermetallic phases | RNDr. Aleš Kroupa, CSc. |

| KJB200410601 | Silver-Indium-Tin Alloys as Possible Lead-free Soldering Materials: Interaction with Nickel and Palladium | Ing. Adéla Zemanová, Ph.D. |

| 2A-1TP1/067 | Research into technologies for high potentional heat transfer from a nuclear source | |

| 106/05/2115 | Diffusion of constituents in Mg-based advanced alloys and composites | Ing. Ivo Stloukal, Ph.D. |

| 202/05/0607 | Synthesis of carbon micro- and nanostructures by plasma technologies | RNDr. Jiří Buršík, CSc., DSc. |

| NMP2-CT-2003- 505504 | European Lead - Free Soldering Network | RNDr. Aleš Kroupa, CSc. |

| 106/04/0228 | The role of Fe, Nb and Mo diffusivity in structure stability of FINEMET and NANOPERM – type alloys | |

| 106/03/1355 | Transport processes during heat treatment in Mg – Al alloys | |

| Z2041904-I003 | Diffusion of gallium in polycrystalline magnesium | Ing. Ivo Stloukal, Ph.D. |

| Z2041904-I004 | Diffusion of 67Ga a 114mIn isotopes along grain boundaries in Ni3Al | |

| COST OC 531.02 | Lead Free Solder Materials | RNDr. Aleš Kroupa, CSc. |

| 106/01/0384 | Diffusion properties of intermetallics with L12 structure: Ni3Ga as a model system | |

| 106/01/0379 | Thermodynamics and diffusion of aluminium and carbon in steels | |

| 106/01/0382 | Turn-back diffusion of interstitial elements in weld joints of steels | |

| 106/00/0173 | Mutual diffusion of substitutional elements in modified Ni3Al intermetallics | |

| 106/99/1179 | Hydrogen permeation in Ni3Al-based intermetallic alloys | |

| OC P3.110 | Simulation of diffusion along grain boundaries | |

| 106/98/1368 | Diffusion treatment of layers prepared by plasma nitridation | |

| 106/98/1367 | Phosphorus and carbon thermodynamics and diffusion in steels | |

| 106/96/0261 | Grain boundary diffusion in Ni3Al intermetallic modified by iron, chromium and zirconium | |

| IAA2041501 | Grain boundary diffusion of nickel in boron - doped Ni3Al, NiAl and in Ni-Al(-B) solid solutions | |

| 106/95/1532 | The influence of Cr, Ni and Si upon carbon redistribution in ferritic weld joints | |

| 106/94/0308 | Simultaneous diffusion of nitrogen and carbon in weld joints of steels | |

| 106/93/0095 | Diffusion of Mo, V and W along high-diffusivity paths in BCC Fe-Cr and Fe-Cr-C alloys and in 9%Cr steel P91 | |

| IA24104 | The redistribution of carbon in wledments of ferritic steels |

Device for simultaneous thermogravimetric and differential scanning calorimetrer analysis TGA/DSC-MS - Linesis PT1000 STA + QMS

Device for simultaneous thermogravimetric and differential scanning calorimetrer analysis TGA/DSC-MS - Linesis PT1000 STA + QMSContact person: Mgr. Ondřej Zobač, Ph.D.

Linesis PT1000 STA + Pfeiffer QMS - device for simultaneous thermogravimetric (TGA) and differential scanning calorimetrer (DSC) analysis, measures both, heat flow and weight change of a sample as a function of temperature or time under controlled atmosphere in the temperature range from RT to 1000 °C.

Differential Scanning Calorimeters, DSC 204 Phoenix and DSC 404 Pegasus by Netzsch

Differential Scanning Calorimeters, DSC 204 Phoenix and DSC 404 Pegasus by NetzschContact person: RNDr. Aleš Kroupa, CSc.

The devices are used for the study of phase transformations in solids. DSC 204 is dedicated for low temperatures (-180 °C to 700 °C) and DCS 404 for high temperatures (to 1600 °C) range.

Setaram PCT PRO – E&E

Setaram PCT PRO – E&EContact person:

It is a fully automated Sievert’s instrument for measurement of gas sorption properties of materials.

Diamond Saw LECO VC-50

Diamond Saw LECO VC-50Contact person:

The diamond saw is ideal for precise sectioning with minimal material deformation. It is suitable for sectioning of extremely hard materials - ceramics or metals.

IR FURNACE MILA-5000 ULVAC-RIKO, Inc.

IR FURNACE MILA-5000 ULVAC-RIKO, Inc.Contact person: Ing. Lubomír Král, Ph.D.

The furnace MILA-5000 is characterized by extremely high rate of heating and rapid cooling of samples in vacuum, protective atmosphere or air.

Laboratory furnace LAC LT

Laboratory furnace LAC LTContact person: Ing. Lubomír Král, Ph.D.

The laboratory horizontal tube furnace with 40mm inside diameter of tube. It can be used up to temperature 1300°C.

Laboratory furnaces Classic

Laboratory furnaces ClassicContact person: Ing. Lubomír Král, Ph.D.

Four horizontal tube furnaces with 40mm inside diameter of tube. They can be used up to temperature 1550°C. The temperature of sample is measured by thermocouple located near the sample. The temperature is stabilized within ± 1°C.

Microtom Leica RM2255

Microtom Leica RM2255Contact person: Ing. Lubomír Král, Ph.D.

The rotary automated microtome which allows precise sectioning of radioactive samples with accurate specimen settings enables to set an exact zero point and angle of cutting.

Furnace Balzers VSG 02

Furnace Balzers VSG 02Contact person:

The vacuum induction furnace with maximum charge of about 0.3 kg. The melting experiments can be conducted under vacuum or in a protective atmosphere.

Furnace MAM-1

Furnace MAM-1Contact person: Ing. Lubomír Král, Ph.D.

The furnace MAM-1 is an arc melter designed for melting samples of approximate weight of 5-20 g under protective atmosphere Ar. The batch is melted on water cooled copper plate and it is possible also suction casting. The maximum melting temperature is 3500°C.

VC-50 saw LECO

VC-50 saw LECOContact person: Mgr. Ondřej Zobač, Ph.D.

Precision saw with the diamond cutting disc is suitable for cutting extremely hard materials.

all publications