Institute of Physics of Materials AS CR, v. v. i. > Laboratories > Laboratories of fatigue of materials

MTS Acumen 12 - Electrodynamic testing system

MTS Acumen 12 - Electrodynamic testing system

Contact: Ing. Ivo Šulák, Ph.D.

The MTS Acumen 12 electrodynamic testing system allows static and dynamic loading up to ± 12 kN for cyclic, tensile, bending and compression tests.

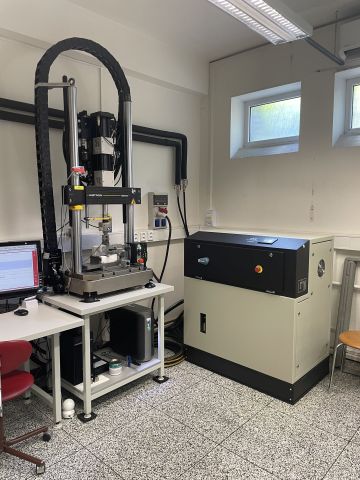

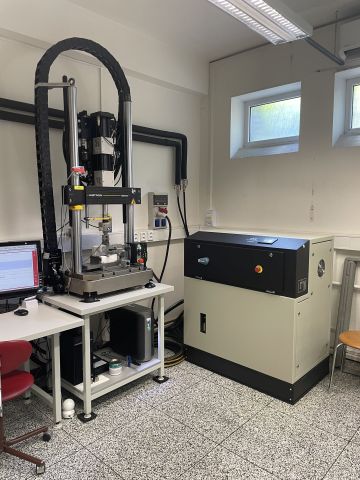

Electrodynamic fatigue testing system Instron E20000

Electrodynamic fatigue testing system Instron E20000

Contact: Ing. Michal Jambor, Ph.D.

The Instron E20000 is a universal testing system for dynamic and static testing of material properties, with a capacity of 20 kN in dynamic mode and 14 kN in static mode.

Servohydraulic pulsator Instron 8872, tension-compression with capacity of 25 kN

Servohydraulic pulsator Instron 8872, tension-compression with capacity of 25 kN

Contact: Ing. Petr Miarka, Ph.D.

The servo-hydraulic pulsator is designed for static and dynamic testing of materials up to a force of 25 kN. The precision test control system allows control of the force and position (displacement) of the piston.

MTS 809 axial – torsional test system

MTS 809 axial – torsional test system

Contact: Ing. Ivo Šulák, Ph.D.

Servohydraulic MTS 809 axial – torsional test system allowing us to perform isothermal fatigue testing with independent bi-axial loading at temperatures from 24°C up to 1400°C.

INSTRON E10000 with linear motor technology, push-pull, torsion

INSTRON E10000 with linear motor technology, push-pull, torsion

Contact: prof. Ing. Pavel Hutař, Ph.D.

An electrodynamic testing instrument INSTRON with closed control loop for static or dynamic testing from very small to high frequencies (100 Hz and more).

INSTRON E3000 with linear motor technology

INSTRON E3000 with linear motor technology

Contact: prof. Ing. Pavel Hutař, Ph.D.

Electrodynamic testing instrument INSTRON with closed control loop for static or dynamic testing from very small to high frequencies (200 Hz and more). Maximal load is of ±3000 N for dynamic testing and ±2100 N for static testing. The system is equipped with temperature controlled chamber INSTRON 3119-605 with a temperature range from -100°C in LN2 atmosphere (-70 °C in CO2) to 350 °C and the internal dimensions of 485×240×230 mm.

ZEISS Neophot 32 Metallographic Microscope

ZEISS Neophot 32 Metallographic Microscope

Contact: Ing. Jiří Man, Ph.D.

The inverted optical metallographic microscope for structural analysis of examined samples in a bright/dark field, polarized light, and differential interferometric contrast.

Resonant system Amsler 10 HFP 1478, 100 kN, push-pull

Resonant system Amsler 10 HFP 1478, 100 kN, push-pull

Contact: prof. Ing. Pavel Hutař, Ph.D.

Resonant pulsator dedicated mainly for fatigue tests at high temperatures. The testing device is equipped by furnace with possible heating up to 1000 °C. Work resonant frequency is controlled by electromagnetic actuator. Test frequency is adjustable and is usually in range of 100 to 130 Hz. Movable crosshead of the pulsator enables application of mean force loads, i.e. asymmetrical fatigue tests.

Resonant system Amsler 20 HFP 5100, push-pull

Resonant system Amsler 20 HFP 5100, push-pull

Contact: prof. Ing. Pavel Hutař, Ph.D.

A resonant electromagnetic pulsator is equipped by accessories for testing compact tensile specimens and 3 point bending test dedicated mainly for fatigue crack propagation measurements. Therefore, the pulsator is upgraded by pair of a camera system for fine measurement of actual crack length. The maximal load is ±10 kN for dynamic testing and ±20 kN for static testing. Test frequency can be in the range of 30 to 300 Hz.

Resonant system Schenck PVQ, 60 kN, push-pull

Resonant system Schenck PVQ, 60 kN, push-pull

Contact: prof. Ing. Pavel Hutař, Ph.D.

Resonant pulsator with mechanical actuator. Possible test frequencies are from 12 to 83 Hz. Test machine is suitable for force controlled fatigue tests of larger samples thanks to the size and stiffness of frame. Dynamic load can be up to 30 kN and mean load up to 36 kN. The pulsator is dedicated for fatigue crack propagation tests of flat specimens (push/pull or push/push tests) or 3 point bending test specimens.

Resonant system ZwickRoell Vibrophore 25, push-pull, temperature up to 1200 °C

Resonant system ZwickRoell Vibrophore 25, push-pull, temperature up to 1200 °C

Contact: prof. Ing. Pavel Hutař, Ph.D.

A resonant electromagnetic pulsator is designed for dynamic testing of materials. Determination of fatigue life (S-N curve) or fatigue crack propagation (CT specimens) can be measured at room or high temperatures (up to 1200 °C).

Servohydraulic system Zwick/Roell Amsler HC25, push-pull

Servohydraulic system Zwick/Roell Amsler HC25, push-pull

Contact: Ing. Petr Miarka, Ph.D.

Compact table model of servo-hydraulic pulsator dedicated for static and dynamic material testing. Pulsator is capable to load the specimen by forces up to 25 kN. Maximum stroke of grips is 250 mm. Testing device is able to control mechanical tests in control regime of force or displacement. Electronic controlling system enables tailoring of a course of the mechanical test according to operator needs. Zwick/Roell Amsler HC25 is mainly determined for fatigue tests with low frequencies and with needs of fine level of control.

MTS 810 servo-hydraulic testing machine for fatigue loading at temperature range from -196°C up to 350°C

MTS 810 servo-hydraulic testing machine for fatigue loading at temperature range from -196°C up to 350°C

Contact: Ing. Ivo Šulák, Ph.D.

Testing system allowing us to perform isothermal fatigue loading at temperature 24°C or when equipped with cryostat at low temperature from -196°C or equipped with environmental chamber in temperature range from -70°C up to 350°C.

MTS 810 servo-hydraulic testing machine for fatigue loading at temperature from 24°C up to 1000°C

MTS 810 servo-hydraulic testing machine for fatigue loading at temperature from 24°C up to 1000°C

Contact: Ing. Ivo Šulák, Ph.D.

Testing system allowing us to perform isothermal fatigue loading at temperatures from 24°C up to 1000°C.

MTS 880 servo-hydraulic testing machine for thermo-mechanical fatigue

MTS 880 servo-hydraulic testing machine for thermo-mechanical fatigue

Contact: Ing. Ivo Šulák, Ph.D.

MTS 880 servo-hydraulic testing system allowing us to perform an independent mechanical and thermal cyclic loading in the temperature range from 24°C to 1200°C.

Ultrasonic system for very high cycle fatigue measurements

Ultrasonic system for very high cycle fatigue measurements

Contact: doc. Ing. Jan Klusák, Ph.D.

Ultrasonic fatigue system pulsating at frequency of 20 kHz. This allows real-time measurement of very high cycle fatigue properties of materials at the number of cycles between 10 million to 10 billion. Measurement is possible under tension/compression and tension/tension conditions. It enables the measurement of SN (Wöhler) curves and fatigue crack propagation rates.

Laboratories of fatigue of materials

Virtual tourTake a Tour |

| The fatigue damage of materials is studied at IPM in the groups of Low-cycle fatigue and High-cycle fatigue. We investigate a crack initiation and propagation under number of load cycles from tens to billions. |

MTS Acumen 12 - Electrodynamic testing system

MTS Acumen 12 - Electrodynamic testing systemContact: Ing. Ivo Šulák, Ph.D.

The MTS Acumen 12 electrodynamic testing system allows static and dynamic loading up to ± 12 kN for cyclic, tensile, bending and compression tests.

Electrodynamic fatigue testing system Instron E20000

Electrodynamic fatigue testing system Instron E20000Contact: Ing. Michal Jambor, Ph.D.

The Instron E20000 is a universal testing system for dynamic and static testing of material properties, with a capacity of 20 kN in dynamic mode and 14 kN in static mode.

Servohydraulic pulsator Instron 8872, tension-compression with capacity of 25 kN

Servohydraulic pulsator Instron 8872, tension-compression with capacity of 25 kNContact: Ing. Petr Miarka, Ph.D.

The servo-hydraulic pulsator is designed for static and dynamic testing of materials up to a force of 25 kN. The precision test control system allows control of the force and position (displacement) of the piston.

MTS 809 axial – torsional test system

MTS 809 axial – torsional test systemContact: Ing. Ivo Šulák, Ph.D.

Servohydraulic MTS 809 axial – torsional test system allowing us to perform isothermal fatigue testing with independent bi-axial loading at temperatures from 24°C up to 1400°C.

INSTRON E10000 with linear motor technology, push-pull, torsion

INSTRON E10000 with linear motor technology, push-pull, torsionContact: prof. Ing. Pavel Hutař, Ph.D.

An electrodynamic testing instrument INSTRON with closed control loop for static or dynamic testing from very small to high frequencies (100 Hz and more).

INSTRON E3000 with linear motor technology

INSTRON E3000 with linear motor technologyContact: prof. Ing. Pavel Hutař, Ph.D.

Electrodynamic testing instrument INSTRON with closed control loop for static or dynamic testing from very small to high frequencies (200 Hz and more). Maximal load is of ±3000 N for dynamic testing and ±2100 N for static testing. The system is equipped with temperature controlled chamber INSTRON 3119-605 with a temperature range from -100°C in LN2 atmosphere (-70 °C in CO2) to 350 °C and the internal dimensions of 485×240×230 mm.

ZEISS Neophot 32 Metallographic Microscope

ZEISS Neophot 32 Metallographic MicroscopeContact: Ing. Jiří Man, Ph.D.

The inverted optical metallographic microscope for structural analysis of examined samples in a bright/dark field, polarized light, and differential interferometric contrast.

Resonant system Amsler 10 HFP 1478, 100 kN, push-pull

Resonant system Amsler 10 HFP 1478, 100 kN, push-pullContact: prof. Ing. Pavel Hutař, Ph.D.

Resonant pulsator dedicated mainly for fatigue tests at high temperatures. The testing device is equipped by furnace with possible heating up to 1000 °C. Work resonant frequency is controlled by electromagnetic actuator. Test frequency is adjustable and is usually in range of 100 to 130 Hz. Movable crosshead of the pulsator enables application of mean force loads, i.e. asymmetrical fatigue tests.

Resonant system Amsler 20 HFP 5100, push-pull

Resonant system Amsler 20 HFP 5100, push-pullContact: prof. Ing. Pavel Hutař, Ph.D.

A resonant electromagnetic pulsator is equipped by accessories for testing compact tensile specimens and 3 point bending test dedicated mainly for fatigue crack propagation measurements. Therefore, the pulsator is upgraded by pair of a camera system for fine measurement of actual crack length. The maximal load is ±10 kN for dynamic testing and ±20 kN for static testing. Test frequency can be in the range of 30 to 300 Hz.

Resonant system Schenck PVQ, 60 kN, push-pull

Resonant system Schenck PVQ, 60 kN, push-pullContact: prof. Ing. Pavel Hutař, Ph.D.

Resonant pulsator with mechanical actuator. Possible test frequencies are from 12 to 83 Hz. Test machine is suitable for force controlled fatigue tests of larger samples thanks to the size and stiffness of frame. Dynamic load can be up to 30 kN and mean load up to 36 kN. The pulsator is dedicated for fatigue crack propagation tests of flat specimens (push/pull or push/push tests) or 3 point bending test specimens.

Resonant system ZwickRoell Vibrophore 25, push-pull, temperature up to 1200 °C

Resonant system ZwickRoell Vibrophore 25, push-pull, temperature up to 1200 °CContact: prof. Ing. Pavel Hutař, Ph.D.

A resonant electromagnetic pulsator is designed for dynamic testing of materials. Determination of fatigue life (S-N curve) or fatigue crack propagation (CT specimens) can be measured at room or high temperatures (up to 1200 °C).

Servohydraulic system Zwick/Roell Amsler HC25, push-pull

Servohydraulic system Zwick/Roell Amsler HC25, push-pullContact: Ing. Petr Miarka, Ph.D.

Compact table model of servo-hydraulic pulsator dedicated for static and dynamic material testing. Pulsator is capable to load the specimen by forces up to 25 kN. Maximum stroke of grips is 250 mm. Testing device is able to control mechanical tests in control regime of force or displacement. Electronic controlling system enables tailoring of a course of the mechanical test according to operator needs. Zwick/Roell Amsler HC25 is mainly determined for fatigue tests with low frequencies and with needs of fine level of control.

MTS 810 servo-hydraulic testing machine for fatigue loading at temperature range from -196°C up to 350°C

MTS 810 servo-hydraulic testing machine for fatigue loading at temperature range from -196°C up to 350°CContact: Ing. Ivo Šulák, Ph.D.

Testing system allowing us to perform isothermal fatigue loading at temperature 24°C or when equipped with cryostat at low temperature from -196°C or equipped with environmental chamber in temperature range from -70°C up to 350°C.

MTS 810 servo-hydraulic testing machine for fatigue loading at temperature from 24°C up to 1000°C

MTS 810 servo-hydraulic testing machine for fatigue loading at temperature from 24°C up to 1000°CContact: Ing. Ivo Šulák, Ph.D.

Testing system allowing us to perform isothermal fatigue loading at temperatures from 24°C up to 1000°C.

MTS 880 servo-hydraulic testing machine for thermo-mechanical fatigue

MTS 880 servo-hydraulic testing machine for thermo-mechanical fatigueContact: Ing. Ivo Šulák, Ph.D.

MTS 880 servo-hydraulic testing system allowing us to perform an independent mechanical and thermal cyclic loading in the temperature range from 24°C to 1200°C.

Carl Zeiss Jena Stereo Microscope

Contact: Ing. Miroslav Šmíd, Ph.D.

Binocular stereoscopic microscope predetermined for observation of three-dimensional objects in reflected light.

Contact: Ing. Miroslav Šmíd, Ph.D.

Binocular stereoscopic microscope predetermined for observation of three-dimensional objects in reflected light.

Ultrasonic system for very high cycle fatigue measurements

Ultrasonic system for very high cycle fatigue measurementsContact: doc. Ing. Jan Klusák, Ph.D.

Ultrasonic fatigue system pulsating at frequency of 20 kHz. This allows real-time measurement of very high cycle fatigue properties of materials at the number of cycles between 10 million to 10 billion. Measurement is possible under tension/compression and tension/tension conditions. It enables the measurement of SN (Wöhler) curves and fatigue crack propagation rates.