The seminar entitled Role of defects in cast aluminum subjected to monotonic and cyclic loading will be given by Prof. Angelika Brückner-Foit from University of Kassel, Germany on February 19, 2026, at 10:00 am in the IPM lecture hall. The seminar will be held in English.

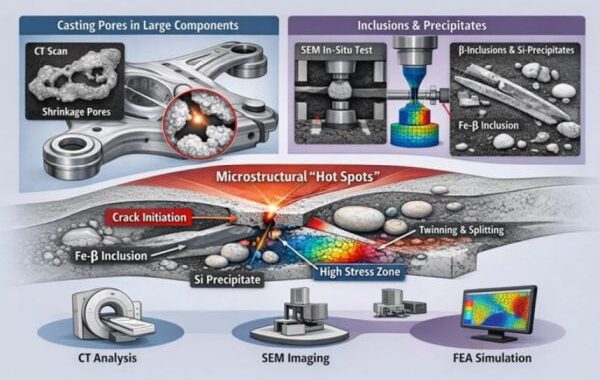

Cast aluminum components are crucial in the mobility sector for manufacturing complex structural parts in near-net-shape form. Their structural integrity depends heavily on casting defects, which can be minimized but not entirely eliminated by advanced techniques. Casting pores, particularly shrinkage pores with complicated shapes in large components with varying wall thickness, occur predominantly in component interiors. CT scans reveal their three-dimensional geometry, while finite element analyses demonstrate that stress concentrations peak at material bridges, which govern failure under fatigue loading.

The second critical defect class comprises inclusions and precipitates. Silicon-rich precipitates are inevitable in typical casting alloys containing about 10% Si, but recycled materials introduce iron-based intermetallic compounds, most critically needle-like β-inclusions. These β-inclusions dominate mechanical behavior under quasi-static loading and split when loaded perpendicular to their axis due to twinning mechanisms revealed by SEM in-situ tensile tests. Multi-factor analysis combining CT-based microstructure examination, SEM in-situ testing with digital image correlation, and finite element stress analysis shows that interactions between Si-precipitates and β-inclusions create microstructural ‚hot spots‘ from which fatal cracks initiate.